TYPICAL CUSTOMER REQUIREMENTS

- Process monitoring for safety reasons and to enable fast reactions - to events such as leakages, fire, etc.

- Condition monitoring

- Overview and detailed view of equipment, working platforms, etc.

- Modernization of existing processes

- Process monitoring and recording

- Extension options during process changes

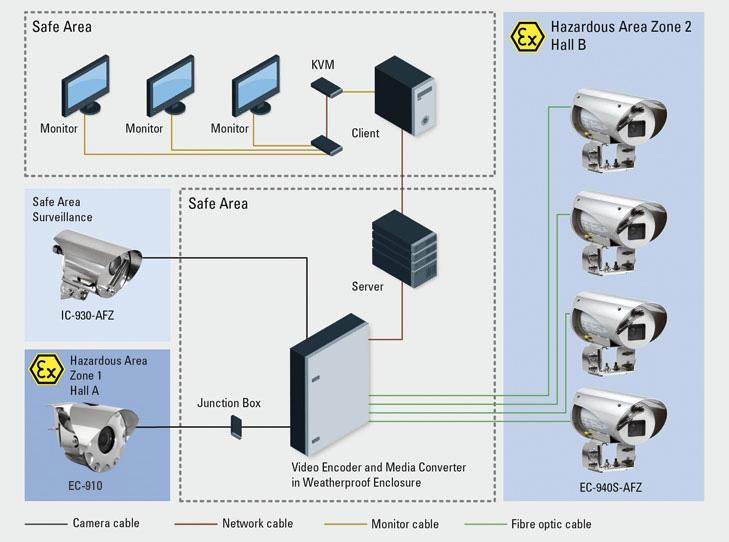

EXAMPLE OF A SYSTEM SOLUTION

CCTV REQUIREMENTS:

For this CCTV system, the client required explosion-protected cameras to monitor two large production halls and several batch reactors. In addition, a safe outdoor area also needed to be monitored. For simultaneous monitoring at different stations, all video data had to be collected in a server-client matrix. The existing analogue CCTV system for sight glass monitoring should be upgraded to a larger, comprehensive CCTV system with better image quality.

CCTV SYSTEM SOLUTION:

To guarantee optimum image quality, the universal EC-940S AFZ camera was used to monitor the outdoor area of Hall B. This full HD IP camera supplies crystal clear images. It is certified for installation in temperatures ranging from -50 °C to +65 °C and, due to its inbuilt wash & wiper system, guarantees a permanently clear view. The EC-910 camera ensures optimum sight glass monitoring in Zone 1 and provides perfect images for the CCTV network. The IC-930 full HD IP camera was used to monitor the safe areas outside of the hazardous zones. Its low-light technology ensures bright, flawless video images.

OUR PRODUCTS AND SERVICES

- Individual CCTV system solutions for the chemical and pharmaceutical industries

- Our services include inspection of the production site

- Excellent images thanks to high-quality, state-of-the-art IP technology

- Entirely new system designs as well as extensions of existing CCTV systems (including testing during operations)

- Fast payback due to elimination of inspection rounds and prevention of process damage

- Full documentation, training and commissioning