UPGRADE OF THE CONTROL SYSTEM

Control and HMI systems are central to any production system and as such are key to its productivity and flexibility. Many are in use for ten or even twenty years. However, to be able to hold one's own in today's competitive market and minimise any risk to the production process, outdated and proprietary control systems should be replaced. Be it discontinued operating systems, missing new security patches or outdated proprietary communication interfaces: a lack of standardisation means more spare parts need to be stored and a decline of expertise on the factory floor and with the suppliers. All this leads to reduced performance and falling competitiveness.

ADVANTAGES OF MODERN CONTROL SYSTEMS

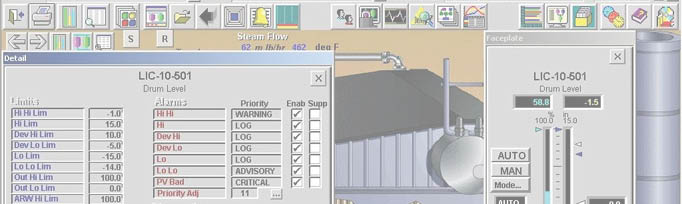

As a general rule, modern control systems use open or standardised interfaces such as Ethernet, OPC or fieldbus solutions. Additionally, engineering and operating systems are based on standard operating systems such as Windows as an all-in-one solution. Focusing on one or a few platforms for the maintenance of the control system reduces cost and effort and results in standardised engineering. The operating and alarm concepts can also be standardised. This way, operators will always keep on top of everything, even in critical situations. New simulation options, redundant concepts and reduced failure rates are further advantages.

Granted: upgrading a control system takes a lot of time and effort, but the "return on investment" for the company is beyond doubt.

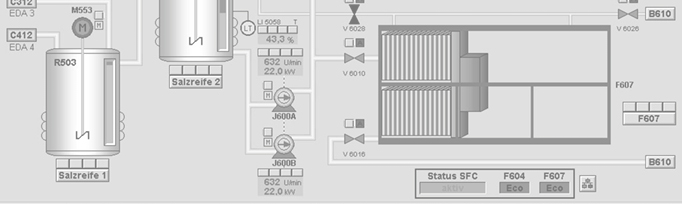

Example of a modern, redundant network solution

R. STAHL's HMI systems as part of modern control systems

R. STAHL is a long-standing partner of the world's leading manufacturers of process control systems, such as Siemens, Emerson, Yokogawa, ABB, Honeywell, and many more. Our automation and HMI solutions boast the latest technologies at all times. They not only perfectly match the latest versions of process control systems, but also established DCS versions that have been on the market for a long time. A large number of adaptations and migrations in the process industries worldwide have already been realised using R. STAHL products, achieving the highest level of customer satisfaction.

Ready for the future: Thin Clients as network-based HMI systems and Remote I/O systems

In the field of Human Machine Interfaces as well as operating concepts R. STAHL is one of the leading providers in explosion protection. We support system operators with state-of-the-art Thin Clients. Thin Clients are network-based HMI terminals that provide a solution for every type of requirement. This ranges from the oil and gas industry with extreme ambient temperatures from -40 °C to +65 °C to safe industrial production areas under cleanroom conditions. All R. STAHL Thin Clients are available with 12" to 22" display sizes, and are configured with the innovative Remote HMI Firmware, enabling extremely secure communication as well as intuitive network administration.

At the control level, we offer the leading Remote I/O-System IS1+. It supports PROFIBUS DP, PROFINET, Modbus RTU/TCP and EtherNet/IP in Zone 1 and 2, and can be combined with other products and technologies regardless of the manufacturer and their process control system. Due to the simple design involving only three components, a hot swap is possible in hazardous areas at any time. Redundancy and intelligent diagnostics ensure safe operation and predictive maintenance. The IS1+ system is suitable for operation in temperatures ranging from -40 °C to +75 °C, and can also be used on offshore platforms and LNG carriers.