A wealth of opportunities are currently opening up for digitalising existing process plants and making them ready for the era of the industrial Internet of Things. Ethernet-APL is increasingly establishing itself as the modern solution for digital connectivity at the field level.It is indisputable that this offers new possibilities, for example through predictive maintenance, improved connectivity and new findings acquired from big data. This is true in theory, at least. But in practice, the path to the digital future can sometimes be laborious, expensive, or both – especially for installations in hazardous areas. Remote I/O helps with this shift while saving money.

Remote I/O technology = easy and practical

Many talks, articles and discussions about the benefits of a digital systems, it is often overlooked that this requires both digital infrastructures and new digital field devices. In addition, many simple sensors and actuators will continue to be used in the digital systems of the future, for which a digital connection is either not available or simply not economical. The gradual migration of existing systems in particular raises the question of how the new digital field devices can be made to coexist most effectively with the installed base. Even today, the space available in control rooms is limited and can only be expanded at great expense.

Continuing with the classic 4...20 mA installation, regardless of whether it is a new system or an expansion, always involves a great deal of engineering work. That's without mentioning the time-intensive installation of cabinets, cables and connections. This is followed by commissioning with the usual trouble-shooting and error rectification steps. This frequently leads to delays and causes the plant to be started up later than scheduled. Modifications or extensions that are later made during operation are usually complex, laborious and expensive – especially when installation also takes place in hazardous areas. We can't forget that often additional valuable space in the control room for isolators and I/O cards basically is virtually wasted.

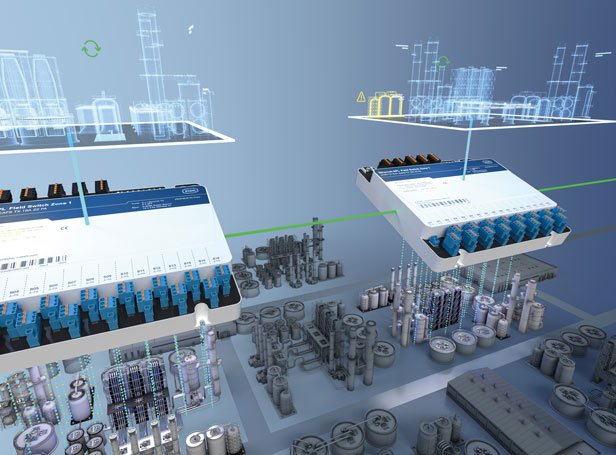

It's important to note that this option is neither cost-effective nor future-proof; rather, it is a dead end. A more effective approach that provides a significant increase in information is to use remote I/O technology instead of traditional point-to-point installation. This paves the way for digital systems, as modern remote I/O systems can be easily integrated into the same networks as Ethernet APL, combining digital and analog technologies.

Open to a variety of signals

Many Remote I/O systems, such as the IS1+ Remote I/O system from R. STAHL, can be used to evaluate almost all types of input/output signals – intrinsically safe and non-intrinsically safe signals, and HART I/O signals. Analogue and temperature sensors (thermocouples, Pt100, etc.), as well as binary signals from contacts, proximity switches, solenoid valves or LEDS, can be processed as well as special signals from solenoid valve islands, high frequencies or joystick applications. Multifunctional, configurable I/O modules have now become established and are proving to be extremely flexible for commissioning and extensions.

Installation even in harsh areas

Remote I/O systems with special explosion protection for Zone 1, like the IS1+ from R. STAHL, are robust and are not affected by extremely hot or cold environments. However, experienced partners who are familiar with Remote I/O and installations in hazardous areas and extreme environments should help to engineer the introduction of these systems.

IS1+ Remote I/O systems are suitable for all applications in Zones 1 and 2 (ATEX, IEC)/DIV 1 and 2 (NEC) and have been used in harsh environments in the oil and gas industry (onshore/offshore) for many years now. The IS1+ Remote I/O has also been used successfully for many years in LNG and FPSO applications, as well as in the chemical, petrochemical and pharmaceutical industries. The systems for installation in Zone 1 do not require any special Ex d or Ex p enclosure. Instead, plug-and-play systems with Ex certification are available in corresponding GRP and stainless steel enclosures for the specific intended purpose and location.

Diagnostics and maintenance made simpler

There are other tangible benefits: While just a few errors can be diagnosed with 4 to 20 mA, the IS1+ Remote I/O system helps with trouble-shooting and asset management thanks to its integrated proactive diagnostics and maintenance at the end of the service life (according to NE107). Maintenance friendly local error indications with LEDS for I/O and modules, as well as alarms and warnings that can be read directly, help the user in their daily operations. Modern maintenance tools which deliver corresponding messages via web servers or OPC UA, for example into cloud systems, are of interest in this context. A hot swap/hot work is possible for all IS1+ Remote I/O modules, even in hazardous areas. Field stations may be opened for maintenance purposes at any time in Zone 1, for example to change an I/O module, without requiring special approval.

And what is the situation regarding costs?

Installations with Remote I/Os achieve huge savings compared to the costs of installations with conventional I/Os. If you look at the CAPEX (capital expenditure), in other words the costs incurred until a plant starts production, the number of required components and work steps alone is reduced. These include cables, I/O cards, isolators, wiring, connections, cabinets, marshalling panels and junction boxes. The expenditure for planning, commissioning and corrections/modifications is also lower, often representing the biggest potential saving. It's also important to mention that less space is required in the control room and, just as importantly, the total weight of the installation is reduced, which is a key factor on ships and platforms in particular.

Aktuelle Kostenvergleiche von 4…20 mA Installationen, Remote I/O und Ethernet-APL zeigen eindeutige Einsparpotentiale zu Gunsten der digitalen Lösungen. Sowohl Remote I/O als auch Ethernet-APL, die beide nahezu kostengleich sind, weisen gegenüber der klassischen Installation CAPEX Vorteile von ca. 20 % auf – natürlich abhängig vom Anlagendesign und Mengengerüst.

What's more, the OPEX (operational expenditure) is also drastically reduced due to the shorter time to production, while the modular hot-swap-capable concept of a Remote I/O makes it possible to shorten or entirely avoid disconnections in the event of maintenance work. The integrated alarms and warnings often prevent even unplanned system downtime, cutting costs in extreme cases. It should also be noted that improved process control is possible, because the high-quality digital communication increases the quantity and quality of diagnostics processes. This improves the product quality.

Four scenarios are used as examples to illustrate the cost differences between conventional wiring and the Remote I/O system IS1+ for applications in hazardous areas. The calculations are based on typical hourly wages in Europe or North America.

Scenario 1: Extremely low number of signals

We assume 16 I/O signals, a distance of 130 metres (30 metres between the field device and junction box, 100 metres between the junction box and control room), with no spares included. While the CAPEX costs for conventional wiring amount to 120,000 euros, these are 100,000 euros for Remote I/O. This is equal to a 17% saving.

Conclusion: Even a very small Remote I/O with just two I/O modules can be better value than a conventional installation.

Scenario 2: Moderate number of signals

In this scenario, we assume 300 I/O signals, a distance of 230 metres (30 metres between the field device and junction box, 200 metres between the junction box and control room) and a reserve of 20 per cent. Remote I/O can reduce costs by one quarter here. The costs of conventional isolators are 1,770,000 euros, while Remote I/O isolators cost 1,320,000 euros.

Conclusion: The nearer the Remote I/O is to the field devices and the further away it is from the control room, the greater the savings.

Scenario 3: High number of signals

The example calculation is based on 1000 I/O signals with a distance of 230 metres (30 metres between the field device and junction box in this case again, 200 metres between the junction box and control room) and a spare of 20 per cent. Remote I/O can reduce costs by one quarter in this case too. The costs of a conventional installation are 5,840,000 euros, while a Remote I/O installation costs 4,340,000.

Conclusion: It is just a guideline value, but using Remote I/O can reduce costs by around 25 per cent in all cases.

Scenario 4: High number of signals and great distances

Now, if we base the calculations on 1000 I/O signals, a distance of 1000 metres and a spare of 20 per cent, the difference becomes even greater. With conventional isolators, the costs are 19,750,000 euros, but these drop to just 5,140,000 euros for IS1+ Remote I/O. This is even though fibre optics was used here due to the distance.

Conclusion: Remote I/O saves a lot of money in applications involving great distances (such as tank farms).

Lighter and cooler on the go

It is also important to consider the aspect of weight, as this is not only important on oil platforms. If you take scenario 3 as the basis, the weight in the conventional installation is 23 tonnes, while if the spare is included in the calculations, this increases by a further 4.6 tonnes. By contrast, the IS1+ Remote I/O is lightweight, weighing just 3.8 tonnes. Remote I/O also offers benefits with regard to space. Following the conventional approach, 50 cabinets are required for 10,000 I/O signals, taking up around 64 m² of space and using 140,000 connection points (10,000 twisted pair field cables, 420 field junction boxes). By contrast, Remote I/O only requires two cabinets with 2.5 m² and 22,000 connection points (60 bus cables, 150 Remote I/O) in the control room.

While the focus used to be on what it cost to build a system, nowadays the importance of operating costs, especially energy costs, is growing. Since fewer cabinets with fewer electronic components are required, less current is used and the requirement for cooling in the control room is also reduced. The power dissipation alone for 10,000 Ex i analogue input signals (2-conductor transmitter) is 18,000 watts for single-channel isolators and 15,000 watts for two-channel isolators, plus the additional power dissipation for the I/O cards in the distributed control system (approx. 625 cards). By contrast, Remote I/O IS1+ requires just 7000 watts. This alone makes it possible to reduce costs by up to 60 per cent. And the installation in the field also significantly reduces the cooling requirement in the control room.

Targeted maintenance

Diagnostics and the integration of a Remote I/O function into plant asset management systems also offer further potential to reduce costs. For instance, fewer personnel are required in the field (and therefore also in hazardous areas). Configuration modifications for I/O functions and in HART field devices are quick to implement remotely. Efficient software tools (DTM, OPC UA, web servers, FDI) are now available on the market to assist with diagnostics and analysis. These are supplemented by local information (such as LEDs, indications) and other information (status, warning, alarm), as well as proactive maintenance functions, such as NE107-compliant status information. For instance, the Remote I/O continuously measures parameters which are decisive for the service life of the system, such as ambient temperature, temperature changes, load conditions or switching cycles. This makes it possible to calculate the expected service life, so that the operator can be notified of maintenance or potential failures at an early stage.

Prospects

Remote I/O systems like the IS1+ from R. STAHL offer huge potential savings for working, commissioning and trouble-shooting, even in small installations. Remote I/O lays the foundations for digital network structures, therefore paving the way for digitalisation. In Kombination mit Ethernet-APL ist Remote I/O die ideale Lösung für Migrationskonzepte aber auch in Neuanlagen. Functions as part of the NOA concept (Namur Open Architecture) may become increasingly important, as they enable advanced diagnostics, condition monitoring and generally improved process transparency in the process industry too. This offers new opportunities for optimising processes.

Further Reading:

These articles might also interest you

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-startseite-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-ueber-den-blog-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-autoren-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-newsletter-expert-mail-279x205.jpg)

Write new comment