Green facilities are enjoying great popularity at the moment: Industrial companies are increasingly turning to environmentally friendly environments which save energy and reduce carbon dioxide emissions. Lighting plays a key role here. Find out how intelligent light management systems not only increase energy efficiency but also reduce operating costs and improve safety.

Industrial companies are increasingly turning to green facilities to save energy and reduce carbon dioxide emissions. These environments use state-of-the-art technologies and digital strategies to minimise their environmental footprint. Modern lighting solutions are an important factor in this. Many plants still use traditional lamps like T8 tubes. The gap between traditional lamps and modern LED technology is growing even wider, having reached a ratio of 70% to 30%. This leads to high operating costs and considerable maintenance requirements. In large plants, the lighting often stays on all the time, as the organisational and technical steps required to switch it off are excessive. In the past, the power costs for lighting often played only a minor role relative to the total energy requirements of a processing plant. But the way in which we think of the energy consumption of lighting systems has changed – not just from an environmental perspective but also due to higher power costs.

An efficient solution can be found in the use of intelligent light management systems. These make it possible to create lighting solutions to meet specific requirements, such as presence control in warehouse areas or daytime-dependent control in order picking areas. Intelligent light management considers the movements and presence of people and measures daylight, meaning that the lighting can be adapted precisely to suit the situation at hand.

The key benefits of intelligent light management include:

- Energy savings: Controlling the lighting based on requirements and time of day drastically reduces energy consumption.

- Sustainability: Energy-efficient lighting reduces carbon dioxide emissions and helps to achieve sustainability targets.

- Easy monitoring and maintenance: Light management systems make automatic status monitoring and fault messages possible, resulting in simpler maintenance and increased safety.

- Flexibility: Intelligent systems are easy to extend and adapt to changing requirements.

However, intelligent light management systems not only offer economic advantages through reduced energy costs, but also psychological benefits for staff. Optimum lighting can boost employees' motivation and mood, therefore improving their performance and sense of well-being.

LED technology is key

Replacing traditional fluorescent tube lights with state-of-the-art LED technology offers numerous advantages. A compelling reason to make this switch is the EU-wide ban on common T5 and T8 fluorescent tube lights, which came into force in August 2023. LED light fittings are not only more energy-efficient but also have a longer service life, resulting in significant cost savings during maintenance and operation. The following example makes the potential savings clear: If 50,000 fluorescent lamps with 58 watts each are replaced in a refinery by LED light fittings, more than six million kilowatt-hours can be saved year on year with an average daily lighting duration of twelve hours.

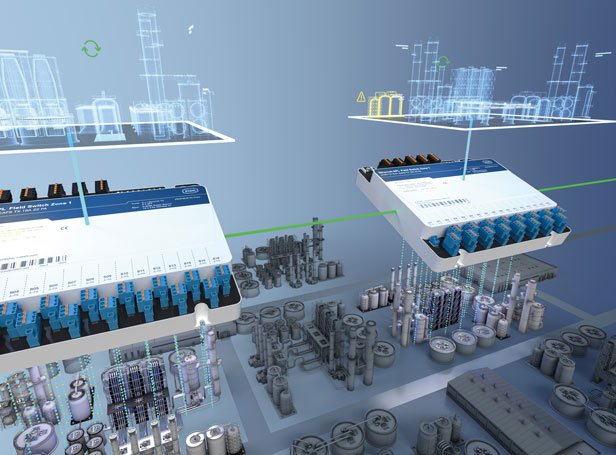

Integration and automation via the DALI interface

For digitising the lighting systems in hazardous areas, R. STAHL uses the digital addressable lighting interface (DALI), which is standardised in accordance with IEC 62386. DALI makes it possible to control light fittings individually and offers bidirectional communication. This means that switching states, error messages and brightness values can be automatically retrieved, making modern preventive maintenance concepts possible. All of R. STAHL's light fittings are available with an optional DALI interface and ensure consistent and modern light management even in hazardous areas. This makes it easier to perform weekly inspections of self-contained emergency luminaires, as they can be continuously electronically monitored. Maintenance cycles can be defined individually for each light fitting, meaning that maintenance can be planned and is more cost-effective.

Implementation and optimisation

Implementation of a light management system begins with careful planning and analysis of the existing lighting situation. A professional lighting calculation looks at the individual requirements and the architecture of the building. During programming and commissioning, the functions are configured and components like light sensors and motion detectors are combined. By optimising a light management system, the plant functions can be adapted and modified via digital interfaces like laptops or mobile devices (such as smartphones or tablets). It is easy to add or move components, which makes the lighting system more flexible and efficient.

Application examples show potential

Sika Deutschland GmbH is an impressive example of the successful implementation of an intelligent light management system. At its Kornwestheim site, Sika introduced a fully digital light solution in two production areas classified as Ex Zone 1. This allows the lighting to be precisely adapted to requirements, therefore not only saving energy but also ensuring that emergency lighting is inspected and documented in a way that complies with the applicable legislation.

In the project for Sika, R. STAHL developed a state-of-the-art digital light solution which is tailored to hazardous areas. By integrating DALI into the building management system based on KNX building system technology, lighting can be controlled intelligently and adapted to operating processes and the ambient brightness. At Sika, lighting is controlled by a KNX DALI interface and regulated depending on daylight and the presence of employees. This results in significant energy savings and improved emergency lighting. And that's not all – automatic regulation of the LED lighting leads to a longer service life. Compared to fluorescent tube lights, the service life increases linearly while the operating duration is shorter.

However, the system is not only used for control purposes; emergency luminaires which illuminate escape routes have to be inspected on a regular basis. Regulations call for a weekly visual inspection of the central power supply and, for battery-powered systems, a check which involves switching on the secondary voltage source. The R. STAHL emergency luminaires that are used feature a DALI interface which automates the weekly inspection and significantly reduces maintenance requirements. This not only replaces inspections, but also means that maintenance can be planned and is more cost-effective.

R. STAHL also uses intelligent lighting within the company, with LED technology making it possible to halve the energy requirements for lighting in the warehouse at the Weimar factory. Intelligent light management has made it possible to achieve additional savings: In the Weimar warehouse, R. STAHL has now reduced its energy consumption by a total of 70%, which is equal to around 22 tonnes of carbon dioxide compared to traditional lighting using fluorescent tube lights.

These articles might also interest you

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-startseite-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-ueber-den-blog-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-autoren-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-newsletter-expert-mail-279x205.jpg)

Write new comment