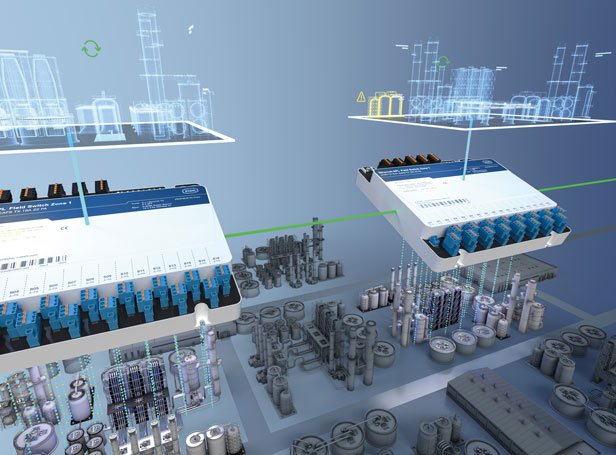

One thing is clear: Digitalisation in all its many forms is increasingly gaining traction the process industry. It is opening up an ever-wider scope of ideas for optimising production and logistics processes for system operators. The project teams involved have an impressive variety of solutions available to them – from many start-ups in the IT industry as well as from established suppliers. However, for a lot of these solutions, explosion protection is proving to be somewhat of an obstacle to digitalisation: Many devices lack the explosion protection that is needed for use in production. But this doesn't have to mean the end of the road. There are a whole host of enclosure systems which can be used to make devices like gateways, RFID readers, media converters, switches, WiFi access points and many more suitable for use in hazardous areas. All this is possible in a short space of time and with solutions that are specifically tailored to the device in question.

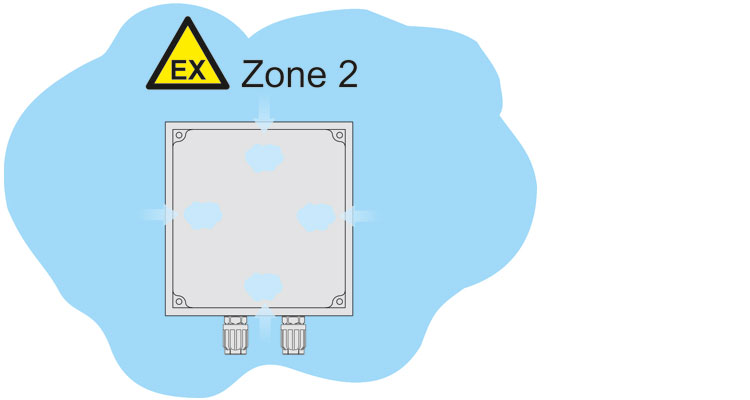

Enclosure systems based on the "restricted breathing" (Ex nR) type of protection are recommended for areas in Zone 2. Why is this? Restricted breathing enclosure systems are characterised by their low weight and can be made of either metal or plastic. Since many IIoT devices and even more WiFi access points use radio signals to transmit their data, the use of plastic enclosures represents an invaluable advantage. In the case of devices with integrated antennas, there is no alternative to plastic enclosures.

The basic principle of restricted breathing – "nR"

The basic principle of restricted breathing comes from the idea that the enclosures being used adequately prevent the explosive mixture of gas and air from entering the enclosures because they are tightly sealed. At the same time, the ignition limit temperature of the potentially explosive atmosphere must not be exceeded on the surface of the enclosure. While this may sound simple at first, some aspects need to be considered in order to strike the perfect balance between the necessary safety requirements and ease of use. The IEC EN 60079-15 standard describes these requirements in detail. The enclosure systems have ATEX or IECEx approval, as indicated by a corresponding marking.

Which devices are compatible with the restricted breathing type of protection – and which aren't?

A clear distinction is made by categorising devices into those which do not produce any sparks or arcs during normal operation, and those which do. The use of sparking devices is greatly limited by the standard, as there is the risk of more explosive atmosphere being drawn into the enclosure due to the inside heating up.

IIoT devices or IT devices in general can, however, be given the all-clear. These devices are usually classified in the group containing devices which operate without switching operates. This makes them excellent candidates for being protected by "nR" enclosure systems like R. STAHL's Series 9851. The supplier of the enclosure system assesses whether and under which conditions a device like a WiFi access point is suitable for installation. Alongside the mechanical aspects, the power dissipation and the associated surface temperature play a significant role. If everything is as it should be, then these solutions can be made available in a matter of weeks.

With or without a test port? That's the question…

The restricted breathing "nR" type of protection is based on the principle that any explosive atmosphere that occurs in Zone 2 can only enter the enclosure to a minimal extent. The sealing that is required for this is provided by the design of the enclosure and the associated components. The enclosure manufacturer decides whether or not a test port will be part of the concept. The requirements for the structure of an enclosure with a test port are less strict.

However, this decision also affects users: An enclosure concept that includes a test port requires regular pressure tests. These tests are carried out manually, which entails a great deal of recurring work for the service staff deployed. This process becomes even more laborious if the enclosures can only be reached using equipment like lifting platforms. By contrast, enclosure concepts without a test port can be used without these regular pressure tests, thereby reducing running costs.

An enclosure with or without a separate connection chamber?

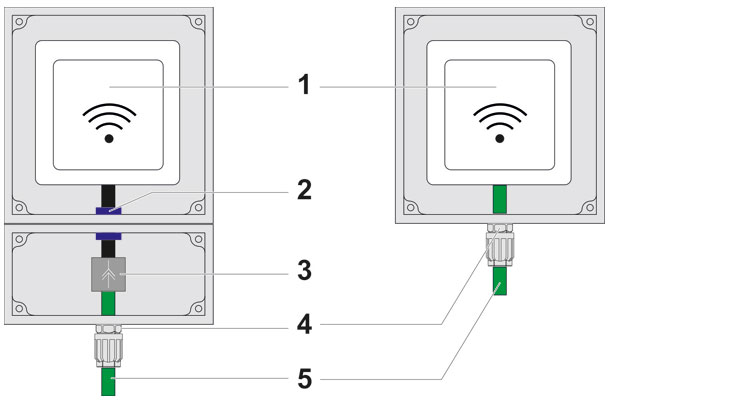

The 9851 enclosure system features a separate connection chamber which has the "ec" type of protection and is permanently connected to the "nR" enclosure part. The conductor bushings for all types of cables are specially designed to provide the required sealing and have been tested over the complete temperature range. Given the roomy structure of most "Cat" Ethernet cables, it's clear just how important these preassembled conductor bushings are. It's virtually impossible to seal these cables using standard cable ends in such a way that they meet the restricted breathing requirements. The structure of the 9851 enclosure system makes life far simpler for the user. The responsibility for finding a suitable cable and ensuring tight sealing throughout the installation's life cycle are transferred from the restricted breathing enclosure part to the connection chamber, where the requirements for tight sealing are not as strict.

1 - Installed device, e.g. WiFi router

2 - Factory-tested "nR" conductor bushing

3 - Terminal

4 - Standard Ex e cable gland

5 - Field wiring

Is a pressure test required for enclosures without a separate connection chamber?

"nR" enclosures which don't have a separate connection enclosure yet don't require regular pressure testing according to their documentation can be found on the market. These very basic enclosures can only be connected using a specified Ethernet cable, which is far more expensive than a normal industrial Ethernet cable. But even in this case, the concept entails some risks which ultimately users must bear. The IEC EN 60079-14 installation standard clearly stipulates that the user on site is fully responsible for correct sealing of the cable, and therefore explosion protection, but they are unable to sufficiently check that this basic enclosure structure has been implemented correctly. The combination of cable gland and cables is exposed to all possible environmental influences in this case. It is highly probable that these influences will impact the sealing throughout the life cycle. Conclusion: "nR" enclosures with an additional connection chamber offer greatly improved safety and operating convenience – both during installation and also throughout the rest of the life cycle.

How is sealing defined and tested for "nR" enclosures?

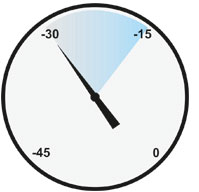

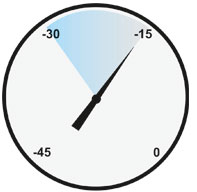

A test pressure of 30 mBar is used for restricted breathing. As a general rule, a vacuum is generated in the enclosure and then the time taken to reach 15 mBar is measured. The specified minimum times until half the value is reached depends on the type of enclosure (with or without a test port) and the type of test (type test or routine test).

The 9851 enclosure series is made up of enclosures without a test port, which means that a minimum period of 180 seconds is specified. The standard also permits alternative measuring methods with higher pressure values and shorter test periods.

Project-specific solutions based on the 9851 enclosure system always undergo a pressure test before delivery. The "nR" area no longer has to be opened on site, as the connection is established via the connection chamber with the "ec" type of protection.

As a user, am I permitted to open the "nR" enclosure?

As a rule, the "nR" enclosure may be opened by users. However, this should only be done in exceptional circumstances. Before opening the enclosure, users must ensure that the installed device is disconnected or that there is no explosive atmosphere. Before closing the enclosure, users must make sure that the seal is not damaged. A pressure test after closing the "nR" enclosure part can be used to detect any leaks. This is why the 9851 enclosure system also features a test port.

Can the installed device be replaced by the user?

If the installed device needs to be replaced, the user must swap it for an identical model. The innovation cycles for IT and IIoT devices are very short, meaning that the original device may no longer be available. In this case, users need to consult the supplier of the "nR" enclosure system.

Conclusion

Enclosure systems like Series 9851 from R. STAHL are a flexible and quick way to use innovative IT and IIoT devices. This paves the way for system operators to achieve greater efficiency in logistics, status monitoring and maintenance of systems, as well as many other digitalisation applications. When choosing the enclosure system, users should note that the available concepts offer varying degrees of safety and complexity in operation. Combined enclosure systems with a separate connection chamber and ex-works wiring offer decisive benefits for use.

These articles might also interest you

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-startseite-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-ueber-den-blog-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-autoren-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-newsletter-expert-mail-279x205.jpg)

Write new comment