For an alert to trigger the correct response, people and technology have to be closely attuned to each other. Visual signals not only provide alerts in hazardous situations, they also ensure seamless processes through different colour patterns.

The colour shows the way! Just like on the roads, green stands for OK, yellow means caution and may require further action to be taken, and red issues a warning or notification of a critical status. Users can tell at a glance when there are issues with the status of production machinery and when doors, gates, chambers, vehicles or forklift trucks aren't working as they should. Alerts make up another area of application, for instance in the event of a gas leak at an oil refinery or fuel depot. People's lives are at imminent risk here. A visual alert offers the advantage that it can be seen either by a very specific group of people or by many people at once (e.g. in traffic or around industrial machinery).

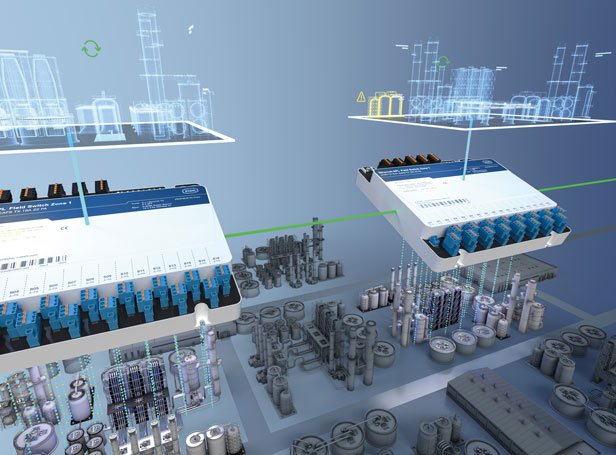

Signaling Ranges

Visual signals, whether they are issued by LEDs, incandescent lamps, halogen lamps or gas-discharge lamps (xenon), are used throughout the entire industry. However, these need to be precisely tailored to their area of application. The challenge is that signals have to be visible during the day and at night, without causing glare or being overwhelming.

The luminous intensity (candela, cd) is used to work out the right type of signalling for a specific application. This is based on the emitted luminous flux (lumen, lm) at a defined solid angle. It is important that only the portion of the luminous flux which is emitted in a specific direction is taken into account for signalling technology data. For an ordinary candle, for example, the luminous flux of 12,566 lumens divided by 4? sr gives a luminous intensity of 1 cd.

Based on the luminous intensity, the effective luminous intensity will be determined to determine the warning and information ranges of signals. Although there are different ways of calculating the signal range, the Blondel-Rey equation is most commonly used. This describes the calculation of the effective luminous intensity (leff), which is used as the basis for calculating signal ranges. However, the widespread radiation energy (joules) is not directly linked to the signal range. Due to the lack of radiating characteristics and the design of the light source, this only provides sufficient information about the signal range.

Flashing signals are more effective

Flashing signals are often sent as visual alerts, since moving light is more clearly visible than static light. R. STAHL collaborated with the Technical University of Ilmenau to examine in greater detail which signal and which flashing pattern are most effective. Studies dedicated to signal perception have looked into various options for blinking/flashing patterns to achieve the best possible signalling/perception effect which goes beyond the theoretical calculations of signal ranges.

LED technology is a game-changer

The lighting technologies used for signalling have been continuously developed over the years. From candles, light bulbs and halogen lamps through to now widespread gas-discharge lamps with noble gas (usually xenon) and state-of-the-art LEDs, which have started to gain traction for the purpose of providing primary status information (constant light), through to sending warning and alert notifications. LEDs in signalling devices are gaining increasing importance in many areas of industry. The reasons for this are their longer service life, robust characteristics, more even emission of light, and variable brightness and colour rendering. However, they are not able to achieve the high peak cd values of xenon flashing units. For this purpose, the signal patterns can be designed to be flexible and longer, a possibility that R. STAHL looked into together with institutes and partners.

The major advantage of this, however, is that the robust LED light fittings are highly flexible. For instance, the YODALEX/2 LED light fitting from R. STAHL that was launched last year boasts a wide range of preconfigured visual signal patterns, such as continuous light, blinking light, flashing light or rotating light, as well as seven lens colours, four output levels and four different light modes. This variety enables operators to adapt the light fitting to their operating location in next to no time. The energy-saving effect shouldn't be forgotten either.

In summary

Fast and clear information can be a matter of life and death – particularly in hazardous areas. In production areas, clear signalling ensures safe processes and optimised manufacturing. R. STAHL assists with choosing the signalling technology in both applications so that the signalling is optimally tailored to the operating conditions.

These articles might also interest you

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-startseite-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-ueber-den-blog-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-autoren-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-newsletter-expert-mail-279x205.jpg)

Write new comment