How can you combine safety, low operating costs and minimal maintenance requirements? The answer is digitalisation or, more precisely, connecting Ex luminaires using DALI.

Lighting in hazardous areas thanks to DALI

lighting system ensure good working conditions, light up dark corners or safely show the way. Nowadays additional demands are placed on lighting solutions, such as extremely low energy consumption and minimal maintenance requirements. Alongside fluorescent tube light fittings, LED luminaires are used in harsh environments and areas where there is an explosion risk. Regardless of these developments, one challenge still remains: In most industrial companies, these luminaires are switched using standard light switches. There are two alternatives here. Either they are not switched at all and are in use 24 hours a day – or they are constantly controlled using an analogue daylight sensor.

This not only leads to high operating costs or high start-up currents when switching – the luminaire does not provide any feedback about its status either. In many cases, inspections are still performed visually. Therefore, in certain circumstances it is left to chance whether a defective luminaire is discovered or reported early. This is different for emergency luminaires with their own power supply. These have to be inspected every week, which, however, results in more work. This means that companies are losing out on a lot of potential, as digital lights are capable of much more nowadays. Examples include adaptive lighting systems in the automotive sector, sensor-controlled lights in offices or luminaires which allow consumers to adjust the colour and brightness to their individual requirements.

More information thanks to a digital twin

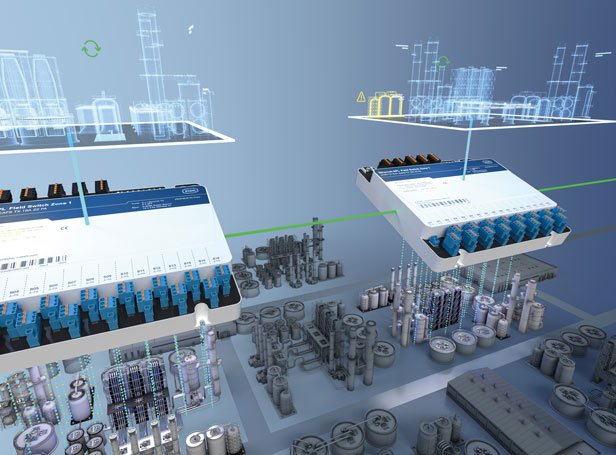

Luminaires can now offer far more flexibility and safety, even in explosion-protected environments. The key words here are digitalisation and the asset administration shell, which provides a digital twin for every luminaire. This gives the luminaire a digital nameplate, which is machine-readable and contains all information about the product throughout the product life cycle. This data is made available in a cloud. The digital twin is available for (almost) all R. STAHL luminaires and makes all document and data available, updating them on a daily basis.

But the options don't end there. Connecting the luminaire using DALI (Digital Adressable Lighting Interface) offers excellent flexibility. This is based on a standardised interface (IEC-standard 62386) for lighting in buildings in order to activate electronic ballasts, daylight sensors and presence detectors, etc. This makes it possible to control and operate all luminaires individually. If the rooms are divided or used in different ways, the lighting can be easily adapted in the software instead of rewiring. DALI can control all luminaires individually, even from far away and display the status centrally on a monitor.

More efficient maintenance

Emergency luminaires are now easier to monitor, as this process has been digitised. Weekly inspections of every single luminaire by the staff are no longer needed and mistakes are prevented. What's more, this is not only true of emergency luminaires – it applies to all types of luminaires. DALI provides all of the information required to plan and carry out efficient maintenance. Many companies hardly plan these maintenance tasks at all, or use Excel to do so. By contrast, using DALI makes it possible to define maintenance cycles for each (type of) luminaire and schedule them in the system. This means that the user can be reminded of upcoming scheduled maintenance in good time. This also starts the spare part purchasing process with plenty of time to spare. The ability to incorporate these maintenance tasks into higher-level building management systems is particularly useful.

To put it in a nutshell: In digital lighting solutions which are possible in all Ex zones (except in zones 0 and 20), all luminaires are connected to each other and integrated in a single system. The luminaires provide feedback about their health status. DALI therefore reduces staff requirements and costs.

At R. STAHL, most luminaires now have a DALI interface, for example all EXLUX linear luminaires for Zones 1 and 2 and for non-hazardous areas (regardless of whether these are fluorescent tube light fittings, LED or standard emergency lighting). The C-LUX compact light fittings and LED universal spotlight are also available with the DALI option. What's more, R. STAHL will soon launch the next generation of LED tubular light fittings, which will also be available with the DALI option.

First steps towards DALI installation

R. STAHL has chosen WAGO as its partner for the DALI master. This comes with the necessary firmware pre-installed. The DALI master is installed on a standard DIN rail in the power distribution board for the lighting system. WAGO also supplies the operating software for light management. The software licences for this can, however, also be purchased directly from R. STAHL. It's important to know that users don't need any special bus line. The topology is open. Up to 64 DALI devices can be connected to a master.

The following steps are required:

- Step 1: Lighting design: General lighting and emergency lighting

- Step 2: DALI planning, grouping, calculating the required DALI master

- Step 3: Planning the wiring, including DALI cable planning

In principle, however, fewer components are required and the master is easy to connect to existing systems. There are now compatible modules for almost any management system. The DALI luminaire is connected via the DALI master, which is in turn linked to the central monitor. The signal from the master to the central unit can other be transmitted by an existing cable, via Bluetooth (up to 20 metres) or wirelessly. However, wireless transmission requires additional infrastructure. In future, 5G will speed up wireless data transmission if 5G licences are available.

Conclusion and prospects

The future belongs to digital luminaires. If the user chooses DALI for their lighting, they will get an extremely flexible lighting system for their daily operations. All modifications, for example resulting from other production processes, can be completed by means of a simple reconfiguration without having to remove or rewire a single luminaire. What's more, luminaires with DALI are suitable for stand-alone solutions without software and monitor (i.e. for decentralised or small solutions) as well as for large complex systems with central monitoring.

The sensor control systems ensure the lowest possible operating costs and even reduce maintenance costs. Ultimately, active light control using sensors maximises the service life of the entire system.

However, connected lighting systems, remote maintenance systems and dynamic emergency lighting systems not only reduce costs and make everyday work simpler through their flexibility – their main benefit is increased safety, as emergency lighting systems work for many years without any issues.

Further Reading:

Write new comment

These articles might also interest you

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-startseite-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-ueber-den-blog-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-autoren-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-newsletter-expert-mail-279x205.jpg)

but i am not sure R.STAHL is ready to provide new connected lighting control system and lighting as well.

I want to have more detailed information if you have any solution.