The digitalisation of the process industry is continuing apace – and the possible uses of digital equipment are becoming increasingly attractive for existing plants too. Technologies like Ethernet-APL enable continuous Ethernet communication to extend into hazardous areas for the first time. But the question is: Does this mean that established technologies like remote I/O are now obsolete?

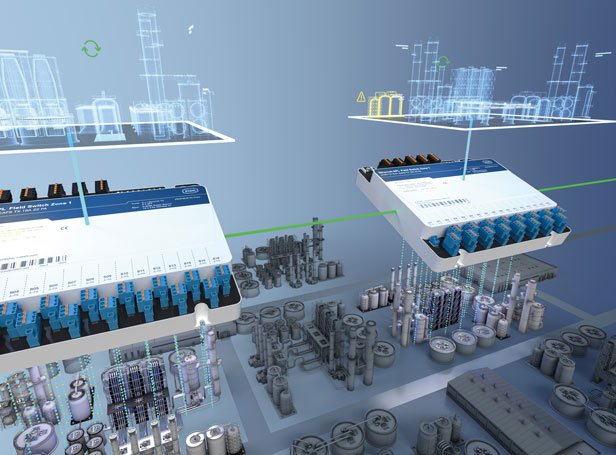

Remote I/O systems serving as decentralised interfaces have been a fixed component of process automation for many years now. They link field devices in process plants to the higher-level control system and move the input/output level from central control rooms to the field itself. This greatly reduces the cabling work required and frees up a lot of space in the control room. Analogue and digital signals, such as 4 to 20 mA, HART data or binary statuses, can be integrated into digital networks like fieldbuses or Ethernet via remote I/O. This simplifies installation, lowers the costs for cables and cabinets, and improves the signal quality by reducing potential sources of interference. And that's not all – modern remote I/O solutions boast diagnostics and maintenance functions which boost system availability and make it easier to digitalise existing systems.

A new communication technology, Ethernet-APL (Advanced Physical Layer), is now in the process of revolutionising the physical layer – and rendering analogue interfaces between the control system and field device obsolete. How is this? Ethernet-APL makes it possible for digital communication to extend directly to the field device, even in hazardous areas of Zones 1 and 0. With a transfer rate of 10 Mbps and a range of up to 1000 m, Ethernet-APL also offers an intrinsically safe power supply for field devices. These features make Ethernet-APL the preferred choice for digital process automation in new systems. But some field devices and applications benefit more from this technology than others:

- Inexpensive devices and applications: Basic sensors and actuators like proximity switches and solenoid valves aren't likely to be equipped with Ethernet interfaces anytime soon. In such cases, it is more cost-effective to establish the devices' Ethernet connection via remote I/O.

- Slow device adaptation: Field devices compatible with Ethernet-APL will be developed and distributed gradually. Remote I/O makes it possible to apply existing technologies and new digital approaches in parallel – already using a digital Ethernet backbone.

These two examples alone make it clear that the reality is complex in many plants. At brownfield facilities, i.e. existing production sites, it will be necessary for older technologies like 4 to 20 mA analogue interfaces, fieldbus systems and modern Ethernet-APL infrastructure to co-exist for many years to come. A complete replacement of all systems doesn't make sense from an economical or technical point of view.

This is why remote I/O systems will continue to play an important role for a long time while digital field communication grows: These act as an efficient interface between conventional technologies and the digital world. Remote I/O systems make it possible to seamlessly integrate existing field devices into modern Ethernet-based networks, therefore creating the basis for gradual modernisation without costly modifications.

The benefits of combining remote I/O and Ethernet-APL

Combining remote I/O and Ethernet-APL offers a whole host of benefits for plant operators and system integrators alike:

1. Cost-effectiveness: Existing infrastructure like 2-wire cables can continue to be used, which significantly reduces the investment costs for modernisation.

2. Flexibility: Remote I/O makes it possible to introduce digital functions like asset management or advanced diagnostics while existing systems and devices remain in operation.

3. Scalability: With remote I/O, new functions and devices can be gradually integrated without interrupting the operation of existing systems.

4. Increased efficiency: Switching to digital communication makes optimised maintenance and diagnostics processes possible, therefore reducing unplanned downtime.

Practical challenges and solutions

Introducing a new technology always comes with challenges. Ethernet-APL simplifies trouble-shooting thanks to standardised diagnostic tools and provides comprehensive information about network and device statuses. At the same time, remote I/O systems can use protocols like HART-IP and OPC UA in order to easily integrate devices with analogue signal transmission into existing management systems. What's more, both technologies also support innovative maintenance concepts such as predictive maintenance. Real-time data from the network and the connected devices make it possible to identify problems early on and take targeted measures.

Future-proof process automation through integration

The answer to the question about whether remote I/O will be replaced by Ethernet-APL is therefore a resounding "no". Instead, practice has shown that both technologies have their own unique strengths and complement each other perfectly. While Ethernet-APL forms the basis for digitalisation, remote I/O promotes the integration and modernisation of existing systems. Together, they offer a flexible and future-proof solution for the process industry. The combination of remote I/O and Ethernet-APL makes it possible to bring together the advantages of the digital world and the requirements of existing systems – a smart way to establish the basis for the process automation of tomorrow.

Further Reading:

These articles might also interest you

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-startseite-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-ueber-den-blog-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-autoren-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-newsletter-expert-mail-279x205.jpg)

Write new comment