ON THE SAFE SIDE: TRANSPORTING AND STORING HYDROGEN SAFELY

To ensure a sustainable future for the hydrogen industry, it is crucial to design the loading, transportation, and interim storage of hydrogen in a safe and efficient manner. The lightweight and volatile gas, produced through methods like electrolysis, is either transported in gaseous form through existing gas pipelines or compressed and then stored deep-frozen in high-pressure tanks and transported by rail, road or water. However, these processes require a significant amount of energy as hydrogen needs to be liquefied at extremely low temperatures of -253°C and undergo multiple compression stages.

These energy costs pose a challenge, especially for long transport routes or long-term storage. An alternative solution is to chemically bind hydrogen by converting it into liquids such as ammonia, methanol, or various liquid organic hydrogen carriers (LOHC). These substances allow for easier storage and more efficient transportation of hydrogen with lower energy requirements compared to its pure gaseous form due to their higher density.

In all these processes, it is crucial to control the safety risks associated with handling the explosive gas. The target is to prevent the release of hydrogen and detect it early if necessary. Continuous monitoring of pressure and temperature is essential. Furthermore, ensuring high efficiency is key, for example, through individually speed-controlled operation of compressors for gas compression.

How can you ensure that everything runs smoothly? By using electrical components and products that are explosion-proof and suitable for harsh environments. At R. STAHL, we support you with our comprehensive expertise - from planning your applications to providing specific solutions and products such as power distribution, lighting and alarming systems. You are in safe hands with us - simply rely on that.

Your partner for safe H₂ logistics

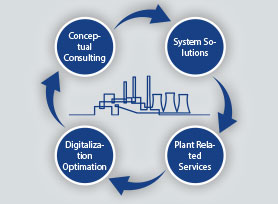

Thanks to many years of experience with hydrogen, our experts at R. STAHL are able to analyse the individual requirements of all hydrogen logistics processes and develop suitable, efficient solutions. They not only support in creating safety concepts for new plants and testing them before commissioning, but throughout the entire lifecycle, customers can rely on being up-to-date with the latest technology and legislation thanks to the expertise of R. STAHL's certified consultants.

Safe and explosion-proof H₂ storage

Storage is possible in gaseous form at 200-700 bar in pressure vessels or in liquid form at -253 °C.

Safe filling for hydrogen transport

Gas can escape during filling for transport via ship, truck, train, or pipelines.

Handle H₂ substances safely and explosion-proof

Convert substances obtained from CO₂ capture into new H₂ energy carriers.

H₂ safely storing and transporting

Handling hydrogen requires a high standard of explosion protection at terminals, storage facilities, pipelines, and during transport to the consumer. R. STAHL's wide range of products, systems, and services supports you in meeting these requirements. Benefit from our many years of expertise in handling highly explosive materials. We are by your side throughout the entire lifecycle of your facilities - with safety as our top priority.

Receive 360° explosion protection from a single source. The safety of your employees, facilities, and the environment is our top priority, without compromise. Our goal is to provide you with comprehensive excellence in safety.

- We create new explosion protection concepts and analyse existing ones.

- We also identify optimisation potentials. Developing customised solutions and seamlessly implementing them into your facilities is a matter of course for us.

- Training and certifying specialised personnel is part of our responsibility as an explosion protection expert.