Constant fill level monitoring in hazardous area, Zone 1

Covestro is a leading producer of advanced polymers operating three different production sites in Germany. Focus is on the manufacture of high-tech materials using the latest technologies, while meeting the highest safety standards.

At the company’s facility in Dormagen, one of the substances being produced is the high-performance adhesive DESMOCOLL®(a polyester/polyurethane polyol), which is needed for a great variety of adhesive compounds worldwide.

The manufacturing process of this adhesive is complex requiring constant control at various production steps, since the medium‘s state is very volatile.

In the past, on-site monitoring of the production process was performed by a staff member. Today, this is done by R. STAHL‘s explosion-proof cameras for hazardous areas, ensuring permanent control of the substance status at all critical points.

The Challenge

In 3 production lines, the product is synthesized in a continuous process (conti-process) under potentially explosive conditions. Therefore, constant condition-monitoring is of the utmost importance due to the product‘s very fast curing times. If the product hardens too rapidly, the result may be unavoidable repair works in the piping system and, consequently, production downtimes.

In the past, on-site inspection and documentation of the production process was carried out by a staff member patrolling 11 particularly critical spots every thirty minutes – a labor- and cost-intensive operation. And simultaneous monitoring of all critical control points was not possible.

As part of automation and to meet the highest safety and security standards, COVESTRO has opted for a CCTV solution: on-site continuous video monitoring of the production process combined with simultaneous monitoring at a central control center.

TAILOR-MADE CCTV SYSTEM SOLUTION

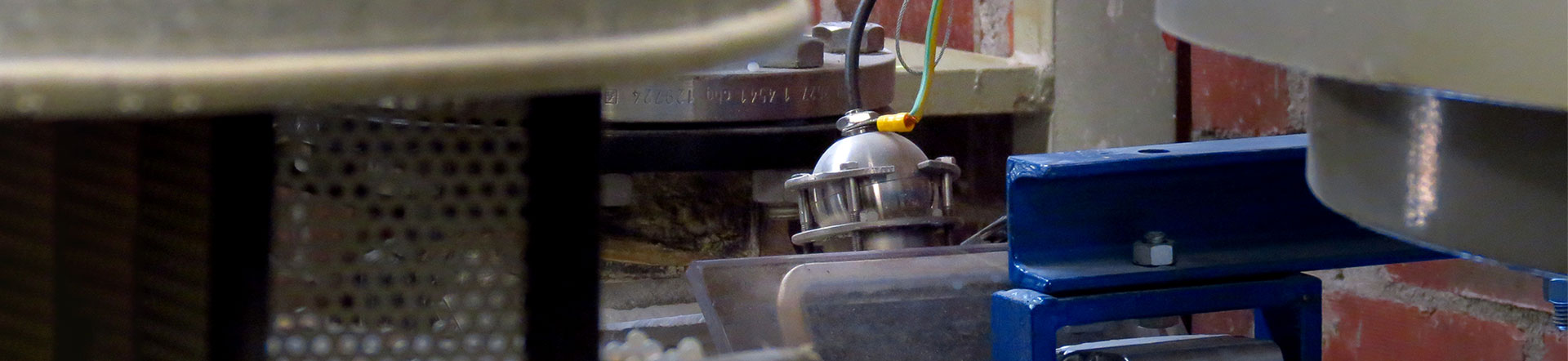

R. STAHL has provided a CCTV system solution for on-site monitoring of these 11 at-risk points using the EC-710 compact cameras for use in hazardous areas. Due to its small and compact design (with a diameter of only 55 mm) the camera has the advantage of being easy to integrate within the inspection window monitoring process. Like all R. STAHL cameras for hazardous areas, the EC-710 compact camera has been designed for extreme temperature applications. The camera is ATEX-certified and approved for operation in temperatures up to +75 °C, and thus fully meets the temperature requirement of +60 °C.

This type of camera is available in different versions featuring 7 different viewing angles (81° wide to 11° tele), so that each type of reactor may be provided with an appropriate camera solution.

In addition, the CCTV solution integrates visualization, both on-site and at the control center to ensure simultaneous monitoring anytime, anywhere.

The Advantages

Cost reduction and continuous monitoring:

Using hazardous area cameras has helped Covestro significantly reduce staff‘s work and thus labor costs, so that the investment in the CCTV system has amortized within a short period of time. Furthermore, continuous monitoring and documentation of all critical points has now become finally possible. Simultaneous monitoring both at the control center and on-site now allows for prompt detection and troubleshooting of any critical changes in the medium, thus reducing downtimes, preventing repairs, and saving time and money.

Prompt detection of process deviations:

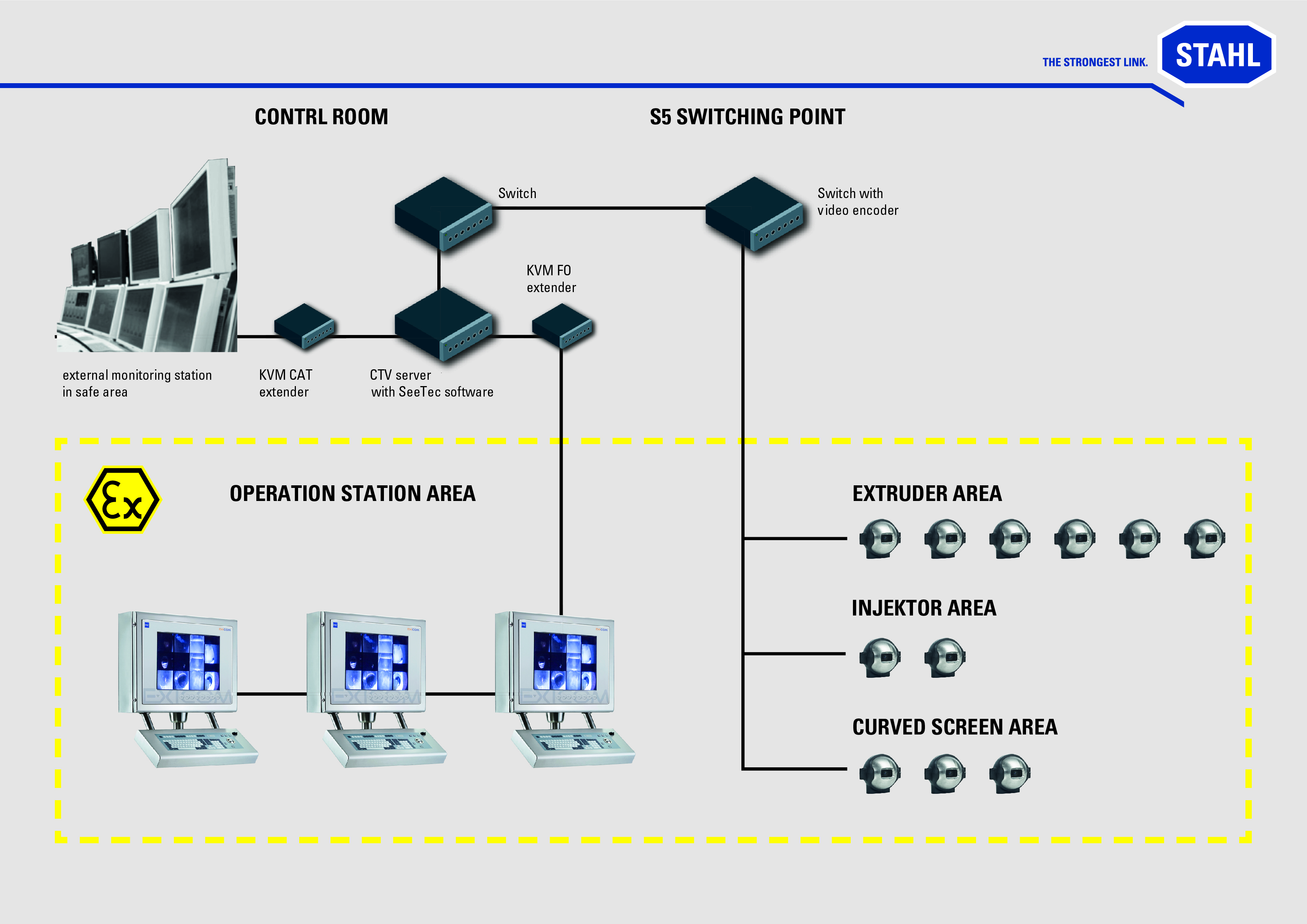

The process images of all cameras are displayed on three 24“ WU human machine interfaces (HMIs), designed as Panel PCs. Images and videos are displayed on these wide-screen monitors with 1920 x 1200 resolution in an easily readable size. Thanks to the simultaneous display of the inspection window images, it is much easier for the staff working on-site to detect any deviations in the process in case of any unexpected changes in the product status. Thus, clumping of the material or even blocked pipes can be prevented.

Display on one monitor using integrated video management software:

The overall CCTV system is operated using the video management software Qognify VMS (Basic, Advanced, Infinity) providing crisp and clear video images on one single monitor. Thanks to the clear structure of the user interface, staff is able to operate the system within a short period of time and to quickly and directly react to any unexpected events, without having to deal with any complex operations. Thus, it represents a good combination of a modern operating concept with tried and tested functionality and ergonomics. In the night mode, for example, colors are changed to improve readability; it is also possible to configure alarm settings, which, in case of an alarm, are activated by keystroke.

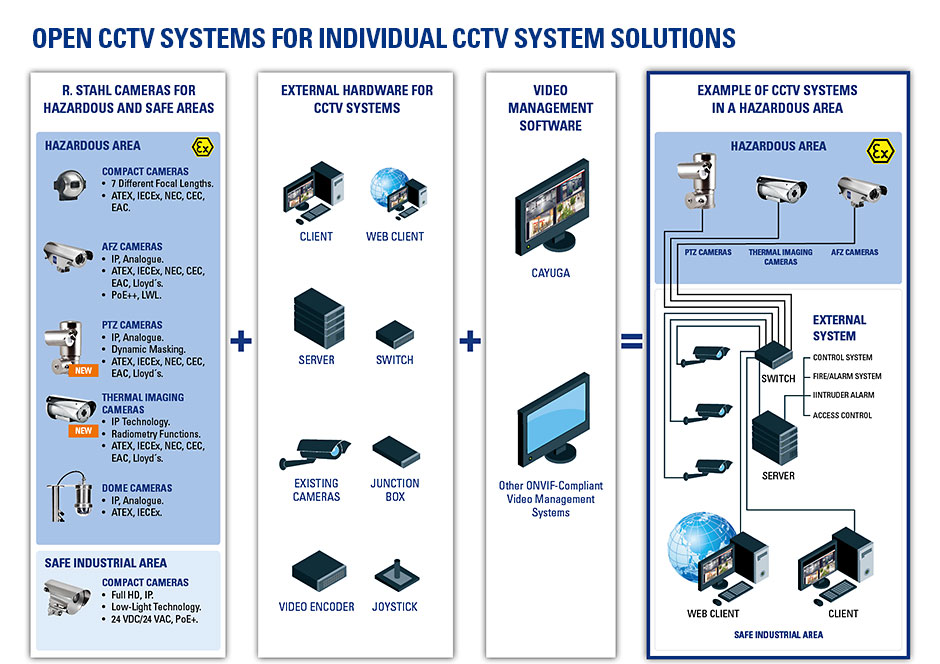

OPEN CCTV SYSTEM

Modular Hardware Architecture:

The new CCTV system in the hazardous area is designed as an open system, making it expandable with further cameras as and when required. Our other explosion-protected cameras such as the zoom or thermal imaging cameras, existing camera types as well as PCs / servers or switches can also be integrated into the system.

Long lifecycle:

Our CCTV systems usually have a lifespan of about 10 years.

Specifically, this means that plant operators will benefit from:

- 10 years of improved control function in the hazardous area.

- 10 years of cost savings.

- 10 years of fewer repairs and possible downtime.

- 10 years of R. STAHL's maximum reliability.

To keep the introduction to the new system as simple as possible for the on-site staff, we pre-configured and documented the system, and after successful commissioning our project manager handed it over to COVESTRO.