Lights on, Paint Applied. Modern LED Tube Lights for high-quality paint production

Wanting to modernise their workshops and production facilities, leading paint manufacturer “Karl Wörwag Lack-und Farbenfabrik GmbH & Co. KG” relies on LED tubular light fittings from R. STAHL. They have provided the right solution for the demands of high-quality paint production, with essential uniform illumination to ensure high quality paint jobs.

The challenge: Modern LED light sources will come with a complete different lamp physics than fluorescent lamps. Reliable solutions are needed to ensure the best possible illumination of factory halls and production facilities. Additionally, explosion protection is a must. Solvent-containing paints can cause explosive atmospheres to happen. Therefore, ignition hazards caused by LED non-compliant material must be avoided, at all costs.

Efficient, Economical, Enduring.These are the key words for R. STAHL’s lighting solutions. A perfect fit for the needs of Karl Wörwag. What's more: the customer knows that he has a partner at his side who has developed one of the first industry approved product series of tubular light fittings in a silicone-free design with maximum explosion detection.

Lighting Solution for the highest demands

LED tubular light fittings are an efficient alternative to conventional linear luminaires in a conventional housing. Slim, lightweight and long lasting (with over 100,000 operating hours). These vibration-resistant systems, protected by IK10+ (20J) impact-resistance and a protection class of up to IP68, have a range of applications outside demanding industrial environments and confined spaces. They are also ideally situated as a modern, economical solution for standard-compliant general lighting in factory halls and production areas.

Significant cost savings can be achieved in terms of both procurement and operating costs when installing LED tubular light fittings. For instance, 30 devices from the 6036 series, measuring just 140 cm in length, provide illuminance of around 500 lx, which would typically require 35 linear luminaires, each with two 36-watt fluorescent tubes.

Results? On one hand, this reduces the number of light fittings required. On the other hand, it also reduces energy usage, since the power consumption of the tubular light fittings is around half that of conventional lighting solutions.

LED Tubular Light Fittings – For Paint and People

Optimal and all-embracing light is not just about the paint. It is also a DIN EN 12464-1 prerequisite for the lighting of indoor workspaces. In comparison with conventional fluorescent, gas discharge or halogen lamps, differences in lamp physics have to be taken into account in modern LED luminaires: This applies to illuminance (lx), luminous flux (lm) and luminous efficacy (lm/W).

For accurate colour perception, the colour rendering value is also important: with good colour rendering values of at least 80 Ra, the LED tubular light fittings of the 6036 series meet indoor requirements. R. STAHL also considers the optimum colour temperature for both the maximum attention and the maximum well-being of employees. To this goal, three different versions are offered; neutral white at 5000k, cool white at 6500k and a warmer version at 4000k.

The View from Above: Ex Protected and Silicone-Free

Paint production can naturally lead to a potentially explosive atmosphere. LED tubular light fittings, with their operational safety and material properties, prevent this. R. STAHL guarantees the highest explosion protection and is both ATEX and IECEx certified. To prevent interfering substances that could prevent uniform wetting of to be painted surfaces, special requirements are required for builds. This means, no silicones, separating agents, lubricants, oils or any other foreign substances are used in the design of the equipment.

These systems, approved worldwide for explosion protection zones 1/21 and 2/22, can be installed quickly and easily using pipe clamps. With a short-term, low inrush current, a large number of lights can be connected per circuit breaker without encroaching on the all-important safety requirements.

Professional Lighting Planning. Detailed. Error-Free. On Target.

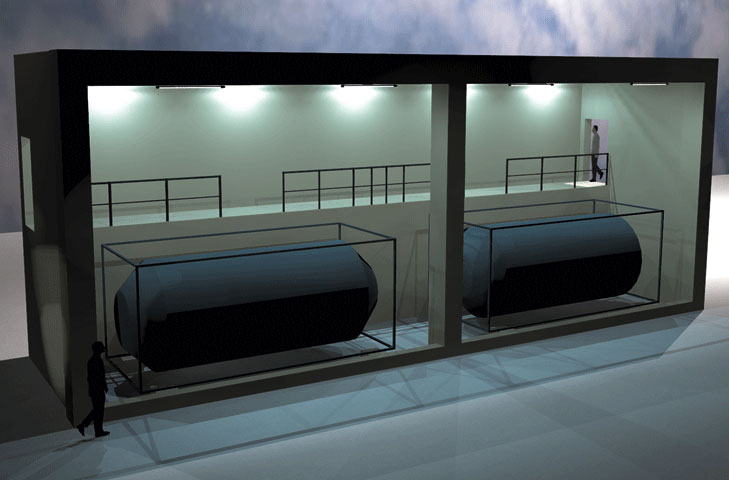

The installation of luminaires was performed for Karl Wörwag, which included a detailed lighting design, including economic analysis for costs, energy efficiency and anticipated maintenance costs. Supported by the ezyLum planning software, the lighting experts from R. STAHL designed the perfect system. All technical lighting factors were matched to the spatial conditions and visual tasks of the customer. This was helped by the capabilities of ezyLum to create photorealistic visualisations of lighting solutions while mapping exact room geometries, including the calculation of surfaces and standard objects. Using ezyLum, R. STAHL could designate the exact number of luminaires at the needed positions and orientations for the required luminous flux and light distribution.

Results? A uniform, nominal illuminance, that conforms to standards, achieved as efficiently as possible for all operating areas.

Conclusion

As a leading supplier of LED luminaires, R. STAHL develops efficient lighting concepts for hazardous and non-hazardous areas of industrial and commercial plants. R. STAHL implemented a very efficient, economic lighting solution for the successive conversion of Karl Wörwag’s factory halls and production facilities through the use of LED tubular light fittings. All the customer needs, from emergency, signal and safety to the more general lighting aspects, were fully met.