A Clean Landing with R. STAHL

Aircraft refuelling is a demanding process. Aircraft tanks must have flammable fuel pumped inside quickly and efficiently. Every lost second adds to the potential disruption of aircraft traffic. Avoiding hazardous situations is imperative. Removing the chance of operating errors is essential. Explosion-protected control devices are the key to prevent hazardous faults. Once installed, sensors monitor all safety-related functions. Slimline 12.5 mm ISpac modules are the ideal choice for tank vehicles. Saving up to 30% space, ex-protected, reliable and completely versatile.

Highest Priority: Safe Refuelling

Air transport numbers are increasing year by year. In 2018 a raise of seven percent brought the number of travellers to 4.4 billion people. Times and turnarounds are so tightly scheduled that errors can cease operations. The volumes of fuel needed is also immense. Around 15 million litres of kerosene at Frankfurt is needed per day. This kerosene, pumped at a pressure of around 3.5 bar, poses a danger of ignition. Electrostatic charge or vapour formation from the fuel tank contribute to these risks. When refuelling operations are not done via an underground supply pipeline dispenser, vehicles made for refuelling are used.

A True Sense of Security

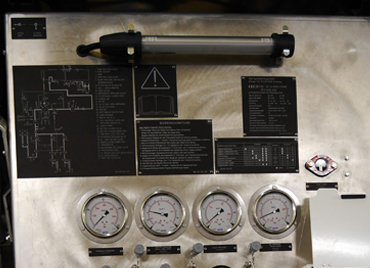

For functional safety and explosion protection, all safety-related machine functions and tank vehicle statuses are sensor-monitored. Intrinsically safe sensors watch the speed of the hydraulic pump. Two-stage overfill protection prevents overfilling. This works by switching off the pump and locking the bottom valve. Monitoring does not just happen during the refuelling process. Grounding clamp connections, valve positions, retraction of lifting platforms, positions of refuelling hoses and filling brackets are all covered.

All values are transmitted to the machine control and thus displayed to the driver. Automatic signal evaluation ensures that no damage or dangerous situations occur due to operating errors. Therefore, in the event of faults, moving the vehicle is only possible if the lifting platform is correctly retracted, and hose holders and other equipment have been stowed away correctly.

ISpac Modules – Reliable, Efficient and Secure

ROHR Spezialfahrzeuge GmbH are a world-leading manufacturer of special vehicles and aircraft fuel system vehicles. To meet the challenges above, they are equipped with R. STAHL’s ISpac modules. ROHR produce around 40 refuelling vehicles and dispensers yearly. This subsidiary of Kässbohrer Transport Technik GmbH also produces vehicles to customer requests for aircraft fuel requirements. These vehicles are designed for refuelling a range of helicopters and aircrafts. These include the Antonov AN-225 and Airbus A380 model series. Delivery rates between 100 l/min to 4000 l/min for fuel make them the ideal units for these tasks.

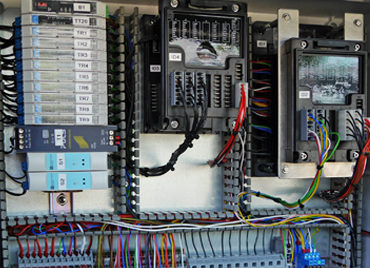

The aircraft refuelling vehicles equip up to 24 sensors to monitor safety-critical tasks. Such as the 9270 series of highly compact switching amplifiers for intrinsically safe transmission of sensor data to the controller. Approved up to SIL 2, the signals are galvanically isolated via relays or electronic outputs. One additional contact detects any line faults between the isolator to sensors and alerts the driver.

The other advantage? More space. Due to their size ISpac modules require 30% less space than conventional isolators. They were installed in the cabinetbehind the passenger seat in a way that optimises the use of space, improving signal density and creating space for future expansions. Installation is tool free, due to pac-Bus. Vibration-resistant installation is ensured.

Complete ISpac Portfolio

Almost every item in the ISpac isolator range from R. STAHL is available in a 12.5 mm version. Slim isolating amplifiers, transmitter supply units and binary outputs create flexibility. Users can build on this for 1 and 2 channel signal transmission solutions. Virtually all ISpac modules that have ATEX and IECEx certification also meet SIL 2 or SIL 3 standards. Incidentally, they are also long lasting. Operational periods have been found to be 15 years. This ensures above-average availability and a high level of fail-safe reliability. What's more, the modules are particularly energy-efficient and designed for use in a wide range of temperatures. They can be installed without the need for tools using pac-Bus or directly on the DIN rail. This means a range of isolators can be combined. Even those from other leading manufacturers

R. STAHL – Aircraft Refuelling in Safe Hands

Explosion protection control and EMERGENCY STOP buttons are also used in ROHR's special fuel vehicles. These devices are installed in refuelling units, lifting platforms and other safety-relevant functions. Control panels have compact push buttons from the R. STAHL 8040 series integrated. This allows control of pumping speed, lifting platforms and other hydraulic functions. Weather and temperature-resistant control devices and components in robust GRP housing are another key feature. Designed to be modular. They can be flexibly adapted to required applications.

In hazardous areas, lighting is of prime importance. A compact version of R. STAHL's LED tubular light fittings provide this function. The pump fittings have slim light fittings 6036 series incorporated. Manufactured to comply with Ex d type of protection, the 6036 series is designed to be long-lasting, impact-resistant and vibration-resistant.

In short

R. STAHL offers comprehensive solutions for potentially explosive areas. From lighting, to operation, to signal transmission. You can develop your perfect system, whether in airfield refuelling or your own industry, in conjunction with R. STAHL.