Industrial Ethernet in Explosion Risk Areas

Fast, flexible, efficient and sustainable. Digitalisation is the most decisive step you can take towards greater productivity and competitiveness. The clear trend: seamless networking, control and optimisation of entire plants, systems and processes. However, all this only works with the right industrial network infrastructure. A well thought-out and future-proof Industrial Ethernet or WiFi technology topology is important. To realise this potential in your plants, you need a partner that understands the needs of optimal data transmission and applicable regulations of explosion protection.

And that is R. STAHL’s mission. We ensure the symbiosis of digital data transmission with reliable explosion protection. This is why we offer explosion-protected products and solutions for the installation of industrial ethernet networks and bring you the automation technology of the future. Industrial WiFi, Industrial Ethernet, and all other interconnected explosion protected technologies for your plant installed with a trained eye and with futureproofing as standard.

Safe and Fast – Industrial WiFi for Industry 4.0 in hazardous areas

With R. STAHL’s Industrial WiFi, your hazardous location is upgraded to the latest in Industry 4.0 implementations. Data Transmission for mobile operating device and the integration of sensors ensure that you are always on top of what your plant is doing.

R. STAHL offers tailor-made Industrial WiFi solutions for hazardous locations, including in Zones 1, 2, 21 and 22. Our easy to install, future-proof solutions are configured to your exact needs.

Industrial Ethernet for future-proof networks

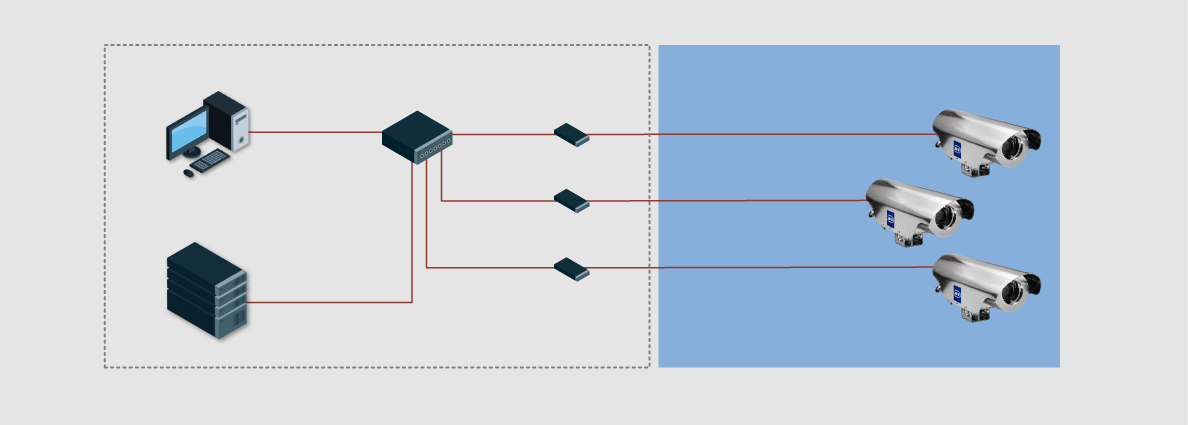

Industrial Ethernet gains more and more importance in process automation and in the manufacturing industry. Our systems allow you to network complete plants in a comprehensive manner, even if these plants are located in a hazardous area.

R. STAHL is uniquely poised to offer these systems due to our years long experience in using fibre optic cables in hazardous locations. In addition to interference-free transmission over a distance of up to 30 km, these cables enable both expansions and conversions without disconnecting the network. Just like ignition-safe operation fibre optic solutions, open, intrinsically safe concepts are setting the new trends in industrial areas. We are, therefore, working with other well-known manufactures on the future standards of networking. Especially with technology such as intrinsically safe 2-wire Ethernet-APL (Advanced Physical Layer) and intrinsically safe 4-wire Ethernet network (100BASE-TX-IS). These are just two examples of R. STAHL’s sustainable digitalisation and network solutions for hazardous locations.

Playing it safe: Industrial Ethernet, IT & Explosion Protection

With the extensive growth of Ethernet in the industrial environment, it is necessary to address the large issue of explosion protection. Laws, standards, recommendations and regulations avoid any danger that may arise from adverse conditions, such as from electromagnetic radiation of radio signals. Standardised types of protection are used for electrical and electronic devices. Which one is selected always depends on the type of hazardous location and the application of the device. The main goal? A symbiosis of the needs of a sophisticated Industrial Ethernet network alongside well thought-out explosion protection.

With 50+ years of experience in explosion protection, as well as our extensive portfolio of Industrial Ethernet products, R. STAHL is uniquely positioned as the right contact for this challenge.

Networked with ignition protection

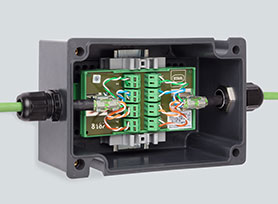

The safe operation of electrical devices in hazardous locations is always carried out using different types of protection. The selection of which will always depend on the form and function of the device. However, there are a few commonalities for Industrial Ethernet Networks in hazardous areas:

Type of protection "i" | intrinsic safety

To avoid sparks and thermal effects, intrinsically safe circuits are used. Electrical energy is then limited in a fail-safe manner. The ignition of an explosive atmosphere is thus reliably prevented. This type of protection enables the connection and disconnection of circuits without needing to turn off the power source.

Type of protection "e" | Increased safety

This type of protection prevents critically high temperatures and the occurrence of sparks inside or outside electrical equipment.

Type of protection "op pr" | Protected optical radiation

Laser sources, such as those used in the course of signal transmission via fibre optic cables, are potentially ignitable. This type of safety, “op pr”, encloses optical radiation in the fibre optic cable and associated connection technologies.

Type of protection "op is" | Inherently safe optical radiation

The type of protection “op is” describes the ignition risk of laser sources. However, unlike "op pr", the solution here is to limit the energy used down to a risk-free level. This type of protection has been proven particularly useful with remote I/O IS1+, as modifications, expansions and maintenance work are possible during operation without switching off the network. A pleasant side effect: Distances of up to 30 km are possible with interference-free transmission.

Type of protection "d" | Flameproof encapsulation

Devices that can ignite an explosive atmosphere are enclosed according to type of protection "d" in a housing that can withstand the pressure of an explosion inside. This prevents the explosion from being transmitted to the surrounding atmosphere.

Type of protection "nR" | Restricted breathing

The construction of enclosures according to type of protection “nR” limits the ingress of explosive atmospheres. In the case of a simple design, the housing seal must be checked regularly.

Additional information about explosion protection here.