IMPLEMENT DIGITALISATION NOW WITH REMOTE I/O AND INTRINSICALLY SAFE ETHERNET

The complexity of machines and advanced systems have increased. Sub-processes need to be seemlessly integrated. Fast, reliable transmission of signals and fully digital access to data are essential for smooth operation. This requires powerful products which are easy to integrate into modern digital network structures – like our Ethernet-based remote I/O systems. They digitalise all process and asset management data from sensors and actuators (e.g. temperatures, levels) and transmit this to the automation level via an intrinsically safe 100 Mbit/s Ethernet network and fibre-optic cables.

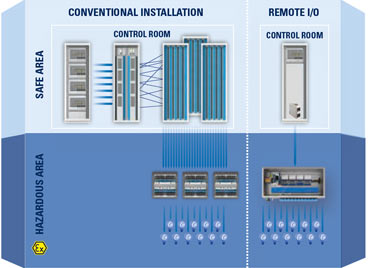

Explosion protected Remote I/O systems from R. STAHL are suitable for diverse functions and the harshest of industrial environments. They are a preferred solution for virtually all tasks in the process industry. This linked graphic of built-in features illustrates the advantages of remote I/O technology installed in hazardous areas for control compared to conventional "point to point" installations.

- 100 Mbit/s, intrinsically safe in Zone 1

With 100BASE-TX-IS – the standard for Ex i 4-wire Ethernet - Up to 90% space savings:

No bulky switch and distributor cabinets in the control room. - Up to 50% cost savings:

Savings in material and working time for field wiring. - Up to 25% faster:

Extensive functions for simplifying commissioning on-site and remotely. - Up to 12 months earlier:

Integrated diagnostics provide an early warning of failures and avoid system downtimes. - 100% HART 7 transparent:

Fully compatible with conventional and HART-enabled field devices and hardware.

For procurement and installation (CAPEX) and operation (OPEX) there is no more cost-effective solution.

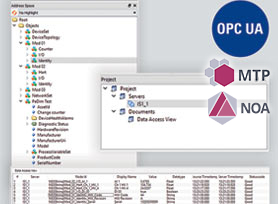

IS1+ is continuously being extended and optimised

IS1+ increases the availability of your systems

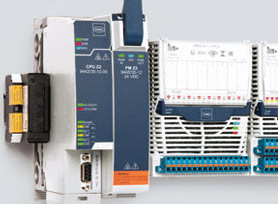

Fieldbus/Ethernet

with either copper or fibre optic cables, intrinsically safe Ex i in zone 1

Multi-protocol CPU

with PROFIBUS DP, PROFINET, Modbus TCP, EtherNet/IP, HART and OPC UA

4-, 8-, 16-channel I/O modules

for Ex i and non-Ex i signals

Field enclosure

in STANDARD, STANDARD+ and customer-specific

Detachable screw and spring clamp terminals

Extensive integrated diagnostics + predictive maintenance

Integrated Ex i supply

for 16 I/O modules in zone 1 and 2

The benchmark in process automation: IS1+ Remote I/O

Continuous development ensures that the Remote I/O System IS1+ is, and remains, the market leading solution. International certificates for explosion protection and ship building is a statement of confidence. The IS1+ System is used over the world in Zone 1, Zone 2, Division 1, and Division 2 areas.

Other advantages of the IS1+ include:

- Easier installation, quicker commissioning and shorter maintenance times.

- Can be used in extreme environments of -40 °C to +75 °C and are thus also suitable for offshore systems and LNG tankers.

- Long service life of at least 15 years even under harsh environmental conditions.

- Detailed diagnostics ensure safe operation and enable predictive maintenance.

- Can be combined with other products and technologies regardless of the manufacturer and process control system or controllers.

- Flexible use thanks to intrinsically safe components and network connection – compatible with almost any automation system.

IS1+ is thus the ideal solution for your automation tasks in the process industry. In the Extended I/O version, IS1+ also helps you with modern digitization concepts.

IS1+ fits everywhere

Ideal for extending or building installations, the IS1+ Remote I/O Systems is suitable for control and applications in hazardous areas or harsh industrial environments. R. STAHL's IS1+ is found throughout the world in the petrochemical, pharmaceutical, machine building, food & beverage and oil & gas industries. It is also perfect for areas where space is constrained and weight matters, such as on FPSO and LNG tankers. Many I/O-modules allow the system to adapt for different environments and situations.