Explosion-protected solutions by R. STAHL

Oil and gas extraction from underwater deposits requires a vast array of explosion-protected components, systems and solutions, both at sea and on the coast. These are employed for a wide variety of tasks, ranging from the extraction and separation of fossil fuels to the production and storage of transportable products. Some of these tasks are performed on site on floating platforms. Systems ranging from offshore cranes to pipelines back on dry land are also found in this environment. They are generally equipped with units such as ex-protected control cabinets and power distribution boxes. R. STAHL is one of the few industry specialists which offers a comprehensive portfolio, as well as extensive expertise in the maritime oil and gas sector and related fields.

Explosion-protected equipment for the maritime oil and gas sector

The response to the different requirements that arise from typical applications and systems in the oil and gas industry is showcased in a series of concrete technical solutions, which also serve to illustrate the various features and issues specific to explosion protection, as well as different approaches in solving explosion protection problems. In addition to control systems for a multi-phase pump system, a separator control system for processing media, a crane control system and the power distribution board for a heat tracing system, the following overview presents a wide spectrum of add-on components for switching cabinets, including motor control systems and other electrical equipment for the mooring system of one of the world's largest floating production platforms (FPSO), which is located in the Yellow Sea.

Control system enclosure for a pump system

Typical offshore applications in the oil and gas industry include the high-pressure extraction of multi-phase media. A mixture of gas or oil, water, sand and sludge components is pumped by specially designed pump systems with control systems that must be protected against explosions and must have a surface finish that is resistant to maritime climates. This often requires a special coating on the enclosure in addition to suitable material properties. In order to achieve an optimal solution that complies with the specifications and takes into account the built-in components, R. STAHL can make use of any of its wide range of enclosures, for example in the form of the CUBEx series.

Explosion-protected separator control system

Extracted mixtures, for example comprising oil, water and solids, must be properly separated, not only to separate useful substances from unusable substances, but also to comply with environmental protection regulations. Depending on the quantity and consistency of the media, pumps and separators with widely varying outputs are used.

R. STAHL is able to provide explosion protection for the requisite electrical equipment, as well as offering plant manufacturers a comprehensive range of products, solutions and services.

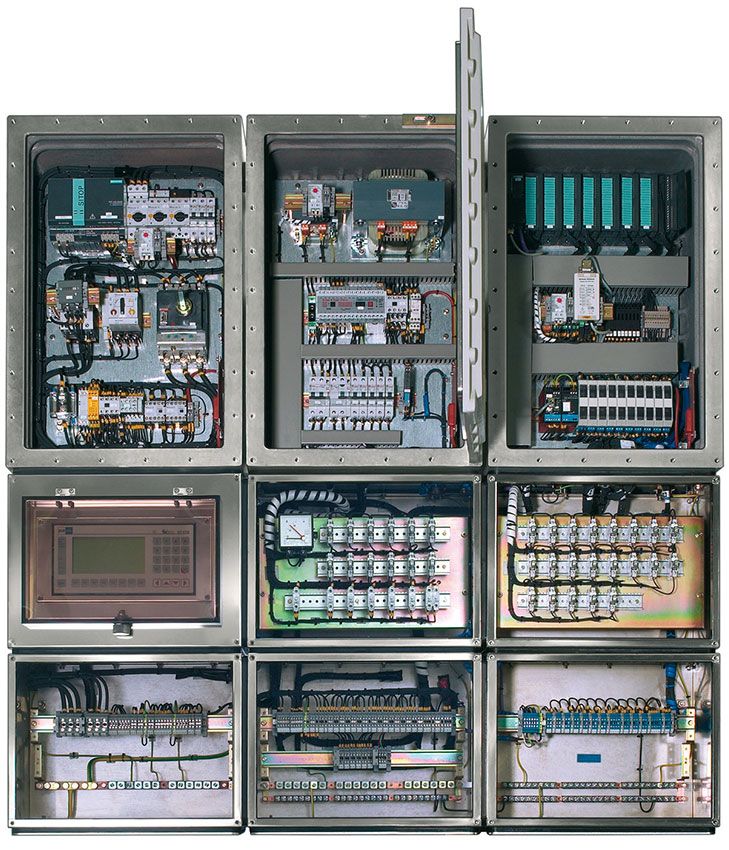

Offshore crane subject to wind and weather

Many drilling platforms are equipped with an offshore, heavy-duty crane, which is used for loading and unloading supply ships, for example. These superstructures and their electrical equipment (which may be installed either directly or in the vicinity) are exposed to the weather even more than many other items of technical equipment in offshore environments. This is why protection against adverse environmental conditions is particularly important here. Horizontal and vertical travel requires high-performance, precise control systems and additional automation equipment.

One example of a suitable explosion-protected system solution would be an Ex de enclosure combination with wall framework and approval for use at a broad range of ambient temperatures. Multiple mounting levels can be added for equipping the enclosure, allowing each flameproof chamber to be fully used. Suitable Ex e connection chambers offer the possibility of connecting the ingoing and outgoing cables to terminals with the appropriate certification. This makes it exceptionally easy to connect and commission the control system at the operating location.

In the standard version, the enclosure door of the flameproof chambers can be used as an additional mounting level. This means that barely any space is lost in the main body of the enclosure, where crucial control equipment is housed. If required, the mechanical functions can be connected to the exterior using special conductor bushings.

R. STAHL also offers a large number of suitable automation modules, such as safety barriers and isolators, which can act as optimal interfaces with the Ex i electric circuit located downstream. These allow virtually any intrinsically safe sensor or actuator to be connected to a control system.

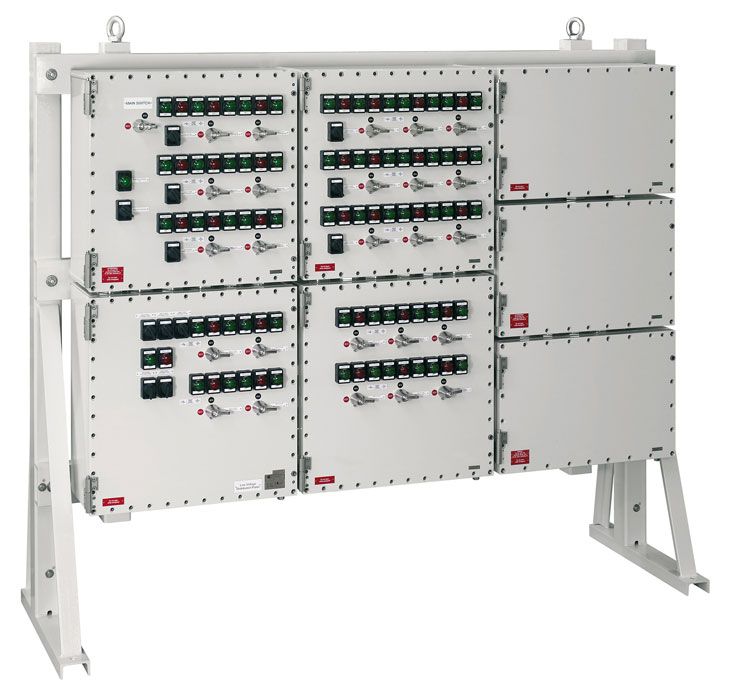

Power distribution board for a heat tracing system

To ensure that oil and gas can be transported through a pipeline without any incident, a heat tracing system is often required in order to maintain or achieve a favourable temperature inside the pipe. To supply these heating systems, transformers are operated on a ring circuit, providing high short-circuit currents at almost every location in the system. These pose their own set of challenges when it comes to protecting power distribution boards against explosions, since under these high load conditions, the systems heat up considerably. R. STAHL's range once again has an effective solution to these problems.

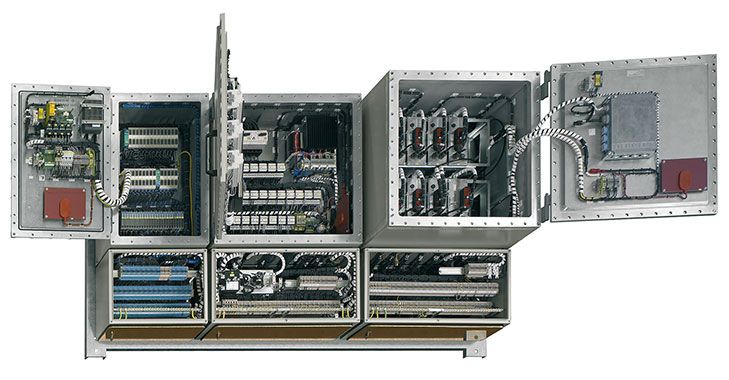

Explosion-protected switch cabinet systems for platform mooring systems

Similar to the challenges faced with offshore heavy-duty cranes, soft yoke mooring systems (SYMS) – the mooring systems used for floating production and offloading platforms – have a particularly tough set of requirements to fulfil with regard to the design of ex-protected switch cabinet systems. In the Yellow Sea, one of the world's largest FPSO (floating production, storage and offloading) platforms, which has storage capacity for 1.8 million barrels of oil, is moored to a mooring tower anchored in the sea bed in Bohai Bay.

The unmanned tower, the FPSO unit and the soft yoke joining them are equipped with a host of electrical components and systems. These include motor control systems, power distribution boards and transformers. The solution that R. STAHL came up with to protect these components and systems from explosions was one that used cabinet systems based on the CUBEx-series modular enclosures.

There was no need for walk-in cabinets with a large footprint. Each of the requisite items of control, power supply and safety equipment was integrated into one switch cabinet for each of the three installation spaces. The limited space available on the mooring tower meant that it was particularly important to have a compact cabinet there.

The external cabinet is entirely made from stainless steel to provide protection from the corrosive atmosphere. This ensures that the system has a long mechanical service life. Inside is a series of Ex d enclosures, various increased safety (Ex e) stainless steel terminal boxes, and power distribution boards with combined (Ex de) protection types. These cabinets are furnished with an Ex heating system and explosion-protected lighting.

Summary

Technical systems employed in oil and gas extraction operations conducted offshore or at sea rely on Ex-protected control systems, power distribution boards, etc. designed, engineered and supplied by industry experts. Fit-for-purpose solutions require a comprehensive, flexible range of suitable electrical components, a modular range of enclosures that is as versatile as possible, in-depth Ex protection expertise, and familiarity with the industry in question in order to create a safe and functionally effective arrangement of combined system enclosures. R. STAHL's comprehensive portfolio combined with many years of experience in the oil and gas industry makes it an excellent partner when it comes to providing Ex protection across the entire spectrum of industry-specific systems such as those used in maritime environments.