Being plunged into darkness can cause fear and panic – emotions that can have serious consequences, and not just in industrial facilities. This is one of the reasons that emergency lighting systems are a requirement all over the world. Whether these luminaires should have their own batteries or be powered by a central battery system is the subject of much debate, however. But at any rate, when it comes to maintenance costs and standard-compliant operation, centrally powered emergency luminaires are probably your best bet for processing plants.

Have all the emergency luminaires in your facility been checked, and the results logged, within the past week? It's certainly a question that comes to the fore if an employee is injured as a result of an accident. It can be quite distressing if the room suddenly goes dark, particularly since visual input accounts for the majority of the information that our brains receive about our environment. If a building or industrial facility experiences a power failure, people must be able to identify the quickest way out of the danger zone. For this reason, international regulations stipulate that emergency lighting that operates independently of the mains must be installed: Green and white safety signs point the way, and emergency luminaires provide the necessary illumination. In Europe, EN 50172 sets out the lighting requirements for escape routes that are to be used in the event of a power supply failure, while EN 12464 covers health and safety in the workplace. Besides ensuring that the emergency lighting is properly installed, the operating company is responsible for regularly inspecting it, testing it, and carrying out maintenance work as necessary. The illumination requirements that the emergency lighting must fulfil are specified in EN 1838; meanwhile, EN 60598-2-22 lays out the electrical requirements for luminaires that serve as emergency lighting.

Operating companies are subject to extensive testing obligations

Given that around one in five luminaires is part of the emergency lighting system in an industrial facility, it is not hard to imagine the burden that regular testing places on a company. For central battery systems and self-contained luminaires alike, regulations stipulate weekly testing with the power source connected, while a daily inspection can also be programmed for central battery systems in order to further increase safety. The weekly check involves testing every single luminaire individually. Additionally, the company that operates the facility must assign somebody to oversee the test/inspection log book used to log the regular inspections and testing. All test/inspection log books covering the previous 4 years must be retained and available for examination.

Self-contained emergency luminaires suffer one major drawback. A drawback that has done nothing to diminish their popularity in the process industry in many regions around the world, most notably the oil and gas industry. This can be largely explained by the fact that these luminaires are completely self-contained and benefit from a high level of availability that isn't compromised by a supply cable being severely damaged. But self-contained luminaires are high-maintenance, as well as being incompatible with automatic logging of test results. The regulations require that these luminaires use a type of battery that lasts at least 4 years under standard conditions. The problem with this is that the conditions in processing plants are rarely what is considered "standard" (20 °C). Ambient temperatures above or below the permissible range significantly shorten the battery's service life, often to 3 or even 2 years. This is another potential headache for operating companies as, generally speaking, the battery cannot easily be replaced while systems remain in operation. In hazardous areas, the plant segment must be tested beforehand to confirm that it is free of gas or the process must be stopped. Since this can involve a lot of hassle and expense, operating companies often try to schedule maintenance to coincide with planned system downtime; but waiting until scheduled downtime risks compromising operational safety within the facility if the emergency luminaires fail before this date.

Another point to consider is the amount of work involved in maintaining this type of luminaire – as they are often installed high up, it may be necessary to erect a scaffold tower in order to reach them. Although it is relatively easy to conduct the requisite weekly tests on self-contained emergency luminaires, it does take a bit of time: It requires on-site plant personnel to manually initiate a self-test or, for luminaires with an automatic self-test function, to check the status of an LED on the luminaire and record it in the test/inspection log book.

Battery-based power supply under controlled conditions

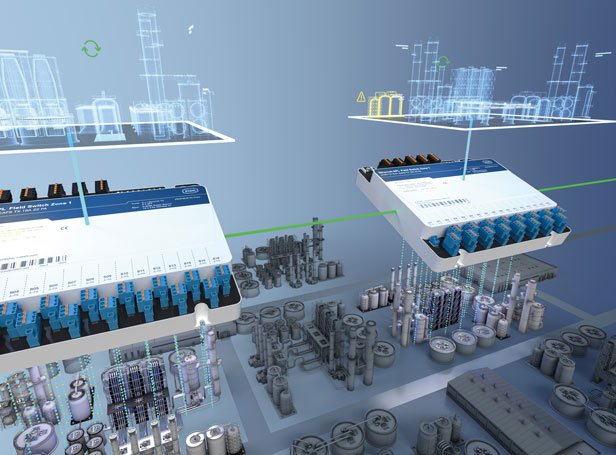

An alternative to self-contained emergency luminaires is centrally powered emergency lighting systems. A central battery system (CBS) powers the emergency luminaires in the event of a power failure and continuously monitors their functional status. Additionally, CBSs enable emergency luminaires to be integrated into the general lighting system. Particularly where hazardous areas are concerned, this radically reduces the costs involved. Because the battery is installed in a safe service room outside of the hazardous area, the capital expenditure and maintenance costs remain relatively low overall. On top of that, the type of battery used here has a service life of at least 10 years under standard conditions – and an electrical equipment room with a ventilation and air-conditioning system is more conducive to standard conditions than the shop floor.

R. STAHL's central battery systems can supply up to 60 lighting circuits; the mainframe can in turn control up to 63 central battery systems. This translates to a potential 3600 lighting circuits at 750 W each. The ease with which the system can be programmed and commissioned is a major benefit. Address modules in the luminaires allow a variety of different emergency lighting scenarios to be configured. R. STAHL has recently come out with an address module for Zones 1 and 2 that features a QR code on its enclosure to enable its address to be scanned in, rather than having to be configured using rotary switches. As a result, configuring the parameters for the emergency luminaire in the central battery system's software is very straightforward.

UPS systems are not a real alternative

Central battery systems are not comparable to uninterruptible power supply systems (UPSs). In the event of a power failure, emergency luminaires connected to the latter system receive an uninterrupted supply of alternating current while maintaining the same output; luminaires connected to central battery systems receive direct current in this situation. These luminaires have an AC/DC detection function that reduces their output at DC conditions to the permitted 50%. The knock-on effect of this is that batteries can be significantly smaller.

But one of the main advantages that CBSs have over both UPSs and self-contained luminaires is their automated monitoring capabilities. The processes of checking the luminaire's functional status and creating an electronic test/inspection log book in line with the applicable standards are fully automated thanks to the central battery system. Additionally, the batteries' capacity must be checked once a year – another task that the central battery system is programmed to undertake.

One argument that crops up repeatedly against central battery systems concerns the cabling: If it were to sustain critical damage in a fire, the emergency lighting would fail completely. But the applicable standard stipulates that suitable protection must be provided when laying supply lines, which must meet the requirements for fire resistance rating F30 if certain fire compartments are being traversed. This means that the cables must be able to resist fire for at least 30 minutes without their essential functional integrity being compromised. Another thing to remember is that cables are much cheaper today than they were, say, 20 years ago.

In summary

Low testing and maintenance costs give central battery systems the edge when it comes to powering emergency luminaires. But they also satisfy what is ultimately the most important safety requirement: Emergency lighting that is always available when you need it. And since testing and documentation obligations are automated, compliance with the relevant standards is guaranteed. This significantly reduces the burden on operating companies.

Further Reading:

These articles might also interest you

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-startseite-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-ueber-den-blog-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-autoren-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-newsletter-expert-mail-279x205.jpg)

Write new comment