R. STAHL and Softing Industrial Automation announced their technological partnership. Together, they aim to drive the development of Ethernet-APL solutions, both in explosion protection and in communication technology. In this interview, André Fritsch, Senior Product Manager for Remote I/O & Fieldbus at R. STAHL, and Thomas Rummel, Senior Vice President of Engineering & Product Management at Softing, provide an insight into the relevant background, aims and technology.

Mr Fritsch, R. STAHL was one of twelve companies that worked on the Ethernet-APL project, establishing the foundations for Ethernet in hazardous areas. To start with, we would be interested in hearing about two-wire Ethernet and its advantages.

André Fritsch: Users' demands for digital communication right down to the field level is nothing new – there are and have always been a range of approaches to achieving this aim. However, this is exactly where users run into problems. The available solutions are very varied, incompatible with one another, proprietary and, above all, typically not suitable for modern digitalisation concepts. Hence the call for "Ethernet in the field" and Ethernet-APL, the answer to this call.

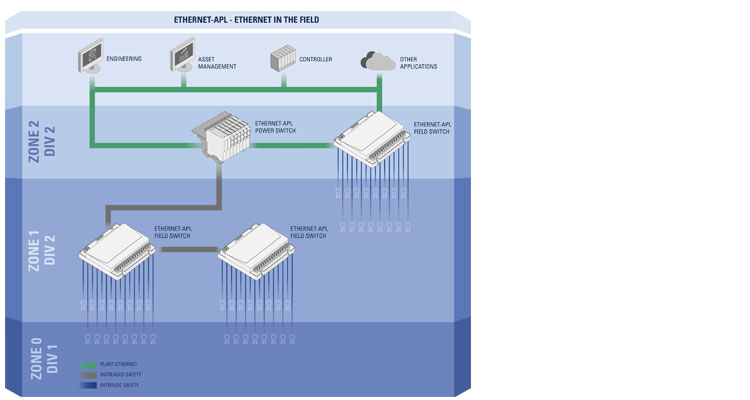

Ethernet Advanced Physical Layer (APL) technology holds the key to digitalisation right through to the field level. In doing so, Ethernet-APL relies on global, open standards from the IEEE and IEC, as well as 2-wire solutions with 10 Mbit/s and suitability for distances of up to 1000 m, standardised as 10BASE-T1L.

For the specific requirements of the process industry, the Ethernet-APL team used this as a basis to work on additions, such as intrinsically safe connection and supply of field devices. This enables the user to implement the globally distributed Ethernet technology, which is used across all industries, even in their process technology systems.

The companies working together as the project team presented their initial solutions at Achema Pulse. Could you give us a general update on the latest developments in Ethernet-APL?

André Fritsch: When it was founded, the Ethernet-APL working group established an ambitious schedule aiming to present products at Achema 2021. The work required to achieve this goal was set out in parallel. The electric parameters regarding supply and communication levels for the Ethernet-APL ports are defined in the Port Profile group. Release version 1.0 has been produced here, which manufacturers can use to get started in device development. The same applies to the requirements for EMC inspections. On the part of the electronic components manufacturer, the new physical layer chips (PHY) that are required can be made available to developers in good time. The associated conformance tests are performed shortly before completion so that devices can be tested. For this purpose, we will make our Ethernet-APL field switches available soon.

To make it as easy as possible to interconnect intrinsically safe Ethernet-APL electrical circuits, we worked out IEC TS 60079-47 "Equipment protection by 2-wire intrinsically safe Ethernet concept (2-WISE)" in record time at IEC level and published it in March 2021. An Engineering Guide is also available to help users implement the new technology correctly in their systems; this guide describes the topologies, explosion protection and planning for users. This means that the technical foundations are available. Manufacturers are currently busy implementing and, of course, testing, testing and testing some more.

Mr Rummel, industrial communication and standardised data exchange are among Softing's key areas of expertise. What is your opinion of Ethernet-APL?

Thomas Rummel: Ethernet-APL will revolutionise industrial communication in the process industry. It meets the installation and safety requirements of the process industry and, with 10 Mbit/s, offers a good bandwidth that is significantly higher than any technology available up to now. With the support of Ethernet, all Ethernet-based communication protocols on the controller and industrial edge level can be used right through to the field device level. This therefore also enables immediate implementation of open architecture concepts such as NAMUR Open Architecture.

You announced your collaboration in the field of Ethernet-APL in mid-June. How did this partnership come about? What joint plans are you implementing and how will they benefit the customer?

Thomas Rummel: R. STAHL has been one of our partners in the area of fieldbus infrastructure components for the process industry for many years now, as well as a good customer when it comes to our FPGA-based communication solutions. With this in mind, we quickly made the decision to pool our strengths in order to develop a joint Ethernet-APL switch product line. Softing Industrial brings its experience with industrial switches and communication solutions to the table; on the other side, R. STAHL provides its expertise in explosion protection and field device power supplies.

André Fritsch: Both R. STAHL and Softing have an extremely customer-focused outlook. That's probably why our partnership is so successful. Each company has its own strengths and weaknesses – and misplaced ambition to reinvent and develop everything independently is counterproductive, and often results in the customer having to make compromises. This is precisely what we have avoided with Ethernet-APL. The customer gets the best of both worlds: Explosion-protected hardware and outstandingly functional software. We also can't overlook the fact that consultation and support services are also available for every task, of course.

The time is right for a state-of-the-art Ethernet infrastructure. There is no real reason to continue working with conventional technology.

When will the first joint solutions be available?

André Fritsch: That's a tricky question to answer at this point in time. Whenever you work with a new technology, you are bound to encounter new challenges and uncertainties. This means that nobody can currently say for sure how well the products from different manufacturers will function as a whole under extreme conditions. As a result, we will perform extensive tests and conduct joint interoperability tests within the Ethernet-APL team. Softing is at our side as an expert partner in this respect, as well. Both companies are addressing their core markets with the planned products and solutions. For instance, R. STAHL will specifically serve the Zone 1 market, since there is great demand for suitable field installation solutions for Zone 1, in particular, as well as for Ethernet-APL components. With these Zone 1 system solutions and our Remote I/O systems, among other concepts, we have been able to develop outstanding expertise over the past 35 years, from which Ethernet-APL users will now benefit.

Thomas Rummel: Softing has been present on the market with Ethernet gateway solutions for fieldbuses in process automation for decades. These are usually installed in Ex Zone 2. We will also focus on installation in Ex Zone 2 or in non-hazardous areas when it comes to our APL switch products. This means that the range of products we will offer as a result of our collaboration will be an excellent addition.

André Fritsch: I think that both companies will certainly have some interesting developments on show at ACHEMA 2022.

Thomas Rummel: Yes, at ACHEMA 2022 we will present both the APL switches and the commModule APL for easy implementation of APL in field devices.

How much work should users expect to be involved in converting their existing infrastructure, for instance using HART or FF, to Ethernet-APL technology?

André Fritsch: The goal that the Ethernet-APL working group set itself is and has always been to make this changeover as simple as possible for our users. With this in mind, for instance, we attached great importance to ensuring that the type A cables that are frequently used for FF H1 and PROFIBUS PA are also suitable for use with Ethernet-APL. Even lower-quality cables, such as those that may be used with classic 4 to 20 mA and HART installations, can still be used, albeit with limitations. To ensure that this is the case, a range of cable categories have been specified; these can be used to upgrade even existing systems without having to change the cabling. Another advantage of Ethernet technology is that completely different systems are able to work together in a single network. For instance, is it possible to construct one system part with Ethernet-APL field devices, while another system part continues to use conventional field devices, bringing them into the joint Ethernet backbone by means of Ethernet-capable Remote I/O systems.

We have already achieved this without Ethernet-APL. Our IS1+ Remote I/O for Zone 1 collects all field device data, including HART, and communicates with the control system via a PROFINET S2 ring, for example.

Thomas Rummel: We have also carefully considered 2-wire fieldbuses. To enable easy implementation and early use of Ethernet-APL, we are planning to integrate functions of our existing products, such as the pnGate, into the APL switches. This makes it possible to convert field devices in systems from PROFIBUS PA to PROFINET in a step-by-step process.

Softing's IT Networks division is a member of the SPE Partner Network. SPE is almost APL's counterpart in the factory automation sector. To what extent, and in what applications, is it possible for both two-wire Ethernet technologies to work together?

Thomas Rummel: Ethernet-APL is based on the IEEE SPE standard 10BASE-T1L and, additionally, establishes a separate, Ex-capable power supply to the switches and field devices. As a result, switches and field devices are specific to Ethernet-APL and cannot be used in standard SPA environments. The interaction between Ethernet-APL and standard SPE takes place via separate switches, which are interconnected using standard Ethernet (100/1000BASE-TX) in a ring or star configuration. This is incredibly practical for hybrid applications in which control tasks from factory and process automation come together. Our IT Networks division works on test solutions for single pair cabling as a dedicated member of the SPE partner network and a member of a number of standardisation bodies around the world.

Previous experience has shown that as a general rule, new communication technologies take around 15 years to establish themselves fully. When do you expect to see a credible ecosystem of APL products and widespread use of this technology?

Thomas Rummel: I would estimate that the ecosystem for widespread use of Ethernet-APL will be available in just five years. The installation approaches for Ethernet-APL offer the advantage that controllers are able to work with their existing Ethernet connections and communication protocols. New products to support Ethernet-APL are only required for the switch infrastructure and field devices.

Softing Industrial will also help to boost the availability of Ethernet-APL devices using technology integration products such as the commModule APL, which will make the development of Ethernet-APL field devices significantly easier.

André Fritsch: Maybe this will all happen even faster than we are imagining today. The time is right for a state-of-the-art Ethernet infrastructure. Our sales of Ethernet-capable Remote I/Os have increased significantly in the past few years. In combination with Ethernet-APL and the smart field devices available at the time, as well as the new solutions for integration into control systems and plant asset management tools, there is no real reason to continue working with conventional technology.

Further Reading:

These articles might also interest you

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-startseite-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-ueber-den-blog-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-autoren-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-newsletter-expert-mail-279x205.jpg)

Write new comment