As part of the energy revolution, liquefied natural gas (LNG) can make an important contribution to supply security as a transition solution. This energy source stands out thanks to its outstanding availability under competitive conditions, with low emissions compared to the combustion of coal and oil. Since the conveyed and liquefied natural gas is highly flammable, explosion protection must be guaranteed throughout the entire value chain.

A smooth transition to a climate-neutral power supply

Over the course of just 20 years, the quantity of LNG (liquefied natural gas) supplied annually around the world has tripled to almost 320 million tons (2018) and, according to industry estimates, could account for more than 15% of the entire natural gas market by 2040. LNG, which is currently almost exclusively obtained from natural gas, is primarily made up of methane, as well as small amounts of other gases like ethane, propane and nitrogen. Currently, its main exporters are Australia and Qatar, while Japan is the largest consumer.

The natural gas, which is liquefied to LNG by deep-cooling it to below -160 °C, has a volume that is reduced by a factor of 1/600 and can therefore be stored cryogenically with a high energy density, as well as being transported on ships or trucks. LNG tankers with a load capacity of up to 265,000 m³ guarantee the gas supply over long distances, even where there is no connection to existing pipeline networks. Furthermore, power generated using natural gas can plug short- and medium-term gaps in the supply during conversion to renewable energy sources in a more environmentally friendly way than other fossil fuels. Gas production from biomass represents an environmentally friendly alternative to fossil gas extraction. Bio natural gas, also known as biomethane, is obtained by fermenting organic substances and can, after processing and CO2 separation, be supplied to the natural gas network.

Consistent Ex protection for the entire process chain

Explosion protection is one of the main challenges involved in natural gas and LNG production. Since the extracted gas mixture is highly flammable, natural gas and LNG are classified as explosion group IIA, temperature class T1 according to ATEX and IECEx. Ignition hazards are not only present during natural gas extraction, but also during liquefaction and reconversion in the LNG terminal, as well as in the event that the cryogenic liquid escapes from transport or storage containers. As a result, the guidelines for constructional and electrical explosion protection must be followed over the entire value chain.

Ex-protected process control in extraction facilities

For decades, R. STAHL has equipped on- and offshore natural gas extraction plants around the world with explosion-protected products and systems for process control, as well as electrical infrastructure and lighting technology. For conventional natural gas extraction, holes must be drilled through the layers of earth and stone until the fossil gas deposit is reached. The borehole must be fitted with piping, concreted and fitted with safety valves at regular intervals. These measures, which also serve to protect the surrounding layers of stone and groundwater, require the drilling process to be continuously monitored.

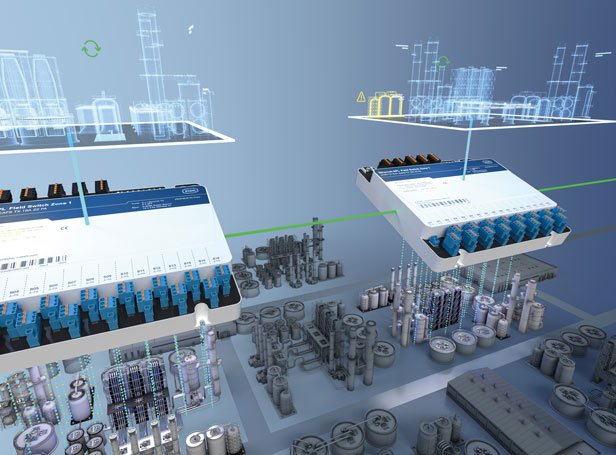

Isolators can be used to ensure safe transmission of measured data to the distributed control system. These are suitable for intrinsically safe point-to-point connection for low signal quantities. For transmitting higher volumes of data using different bus systems or Industrial Ethernet, IS1+ offers, an extremely high-performance Remote I/O system with hot swap capability. It also supports fast, intrinsically safe FO communication in Zone 1 with transfer rates of 100 Mbit/s and enables field devices to be connected in all Ex protection zones.

Power distribution systems for liquefaction systems

The conveyed raw natural gas initially flows through a processing plant, which separates out contaminants and pollutants, in order to obtain almost pure methane. Next, it is conveyed to a liquefaction plant, also known as an LNG train, to be liquefied. Liquefaction using a single- to triple-stage circulation process is associated with high energy consumption due to the deep-cooling and heat dissipation required.

To control the pumps and ventilators needed for the heat exchangers, the systems are equipped with particularly high-performance, explosion-protected motor controls and power distribution boards. R. STAHL implements corresponding Ex protection solutions, depending on the customer's preference and dimensions, with a range of types of protection – for instance, flameproof enclosure (Ex d), pressurized enclosure (Ex p), increased safety (Ex e) or encapsulation (Ex m). The modular enclosure technology enables multiple degrees of protection to be combined efficiently, and control systems and power distribution boards to be configured in a range of sizes; as a result, even extremely high power levels with multiple power outlets are available in hazardous areas. In order to reduce maintenance and servicing costs for the entire LNG train, we recommend connecting the circuit breaker and auxiliary contact to a Remote I/O system, so that the error outputs on the power distribution board can be read out and monitored via the distributed control system.

Control technology minimises load losses

Special tankers with larger and larger dimensions are predominantly being used to transport LNG. Nowadays, the load capacity of a newly built LNG carrier can reach up to 265,000 m³. In spite of the tank insulation, the liquefied gas is heated up during transport and could partly evaporate were it not re-cooled using on-board compressors.

To control the compressors, R. STAHL uses explosion-protected Remote I/O control stations, which transmit the signals from sensors and actuators intrinsically safely, for instance via PROFIBUS DP, to the decentralised control system. Since the available installation space below deck is limited, the machines and RIO stations must be designed to include I/O modules and digital display and message elements in a very compact size. R. STAHL integrates the compressor control stations in robust, Ex e-protected stainless steel enclosures with narrow single, double or triple doors and high-quality, seawater-resistant sealing materials in order to protect them from the saline atmosphere.

Ex protection solutions for reconversion

At the destination, the natural gas is converted back to its gaseous form in regasification units. Alternatively, reconversion of smaller quantities can be performed flexibly at offshore plants, known as Floating Storage and Regasification Units (FSRUs). The reconversion process requires the necessary evaporation heat to be supplied to the LNG; for cost-related reasons, this heat is typically obtained from heat exchangers supplied with seawater. Pump units, which convey the seawater to the heat exchanger, can be equipped with alarm signal emitters, terminal boxes, safety switches and load disconnect switches with AC3 switching capacity. The safety switches safely disconnect the electrical energy supply from machines and system parts for cleaning and repairs.

Since the hazardous zones cover large areas of the plant, explosion protection solutions are not only in use during the actual processing stage, but throughout the entire infrastructure. As well as explosion protection, the use of seawater-resistant enclosure materials, high-quality sealing materials, a vibration-resistant design, and resistance to electromagnetic influences are all deciding factors when choosing which materials and design to use.

Linear luminaires, tubular light fittings and floodlights perform all lighting tasks, both indoors and outdoors. Explosion-protected emergency luminaires powered by batteries ensure that lighting is provided even in case of an error. Audible and/or visual alarm signal emitters are used to indicate warnings or information in the event of a device malfunction in the hazardous area. In addition, ex-protected camera systems, as well as network technology with cable-based and wireless transmission for unrestricted communication in all areas of the plant can be implemented.

Patented protection concept for pressure relief

Before being supplied to the grid, the re-evaporated natural gas is compressed in a compression plant. The motor actuators and power distribution boards, which are required for a number of tasks including control of compressors and supplying the heat exchangers and evaporation systems, can be made significantly lighter and more compact than conventional Ex d enclosures using the patented EXpressure enclosure technology. The innovative pressure relief protection concept enables large yet lightweight Ex d solutions to be designed in classic cabinet format for the installation of electrical and electronic standard components in hazardous areas. This means that the project engineering plans used for non-hazardous areas can be implemented unchanged in Zones 1 and 2. Alongside power distribution boards and control technology, large items of equipment such as transformers and frequency converters can be installed in EXpressure enclosures, providing explosion protection without the need for complex pressurised enclosures. Their lightweight construction, large internal capacity and simple handling make them the perfect choice for both tight spaces and offshore environments.

LNG – the fuel of the future

LNG is primarily used to generate heat or power, and as an energy source for the process industry. Due to its environmentally friendly nature and positive effect on CO2 emissions, it is also becoming increasingly important as a fuel source for ships and trucks. Since the current specifications set out by the International Maritime Organization (IMO) limit the permissible sulphur content in the fuel to a maximum of 0.5%, the combustion of heavy fuel oil in ship motors is only possible if costly exhaust gas cleaning methods are used. As a result, low-sulphur fuels such as LNG represent a future-proof alternative. In order to make use of this alternative, Fuel Gas Supply Systems (FGSSs) must be installedin order to convey the fuel to the motors. These systems include gas tanks, as well as evaporators, compressors, pumps and a central automation system. In order to monitor and pass on the measured temperature, pressure and flow values, valve positions and device statuses, an explosion-protected Remote I/O system and HMI system are installed in the immediate vicinity of the FGSS.

Further Reading:

These articles might also interest you

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-startseite-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-ueber-den-blog-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-autoren-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-newsletter-expert-mail-279x205.jpg)

Write new comment reply