In areas where an explosive atmosphere is likely, only explosion-protected equipment may be used. Electrical explosion-protected equipment can be designed with various types of protection in accordance with the building regulations of the IEC 60079 series of standards. You can find an overview of these technologies here.

Flameproof enclosure (Ex d)

- Principle: The enclosure can withstand a possible positive pressure caused by an explosion and prevents the explosion from spreading to the surrounding area.

- Use: Equipment which could cause sparks or hot surfaces in hazardous areas, such as switchgear, switching systems, control devices, indicating devices, control systems and motors.

- Benefits: Robust design, can be used for various different applications, industrial components can be installed.

Increased safety (Ex e)

- Principle: Equipment is designed so that, when used as intended or in defined exceptional conditions, it cannot generate sparks or excessive heat.

- Use: Ideal for terminal boxes, junction boxes and lighting. Also suitable for some types of motors.

- Benefits: Cost-effective, high degree of safety and highly flexible due to the "configuration approvals" that are possible.

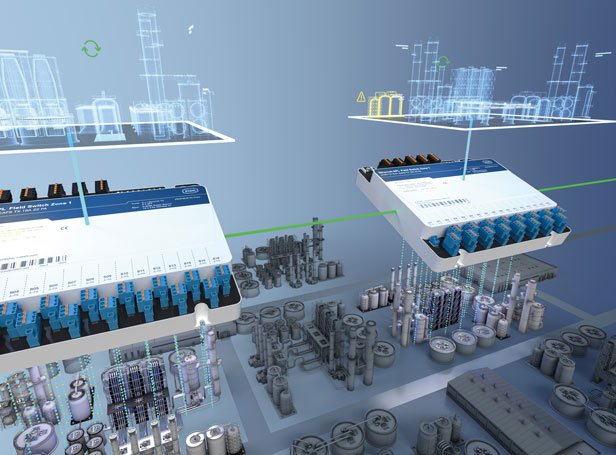

Intrinsic safety (Ex i)

- Principle: The entire electrical circuit, consisting of electrical equipment and cables/lines, is designed so that the energy in the circuit is so low that ignition is impossible, even if there are sparks in the hazardous area.

- Use: Typically in automation technology.

- Benefits: High degree of safety, protection against failure is ensured in "non-hazardous areas", ideal for delicate sensors or actuators.

Pressurised enclosure (Ex p)

- Principle: The formation of an explosive atmosphere inside the enclosure is prevented by using inert gas to maintain a positive internal pressure in relation to the surrounding atmosphere. Or – if necessary – the inside of the enclosure is purged with a constant flow of inert gas which dilutes any combustible mixtures.

- Use: For control systems or analysis systems in hazardous areas and for large motors.

- Benefits: Flexible for large and complex systems, industrial components can be installed.

Protection by enclosure (Ex t)

- Principle: Thanks to the tightness of the enclosure, no dust at all can enter or the amount which can is limited to a safe level. This enables the source of ignition and explosive atmosphere to be separated from each other.

- Use: For equipment in areas with combustible dust.

- Benefits: Industrial components can be installed, simple solution for hazardous dust areas.

Encapsulation (Ex m)

- Principle: Parts which may ignite an explosive atmosphere are embedded in compound such that the explosive atmosphere cannot come into contact with the source of ignition.

- Use: Electronic components and sensors.

- Benefit: Very reliable when subjected to mechanical loads.

Liquid immersion (Ex o)

- Principle: Electrical equipment or parts of electrical equipment are immersed in a protective fluid (e.g. oil) so that an explosive atmosphere cannot come into contact with the source of ignition.

- Use: Effective for transformers.

- Benefit: Basic protection against sparking.

Powder filling (Ex q)

- Principle: Filling the enclosure with a finely grained filler prevents a source of ignition inside the enclosure from coming into contact with an explosive atmosphere surrounding the enclosure.

- Use: Protecting electrical components which could potentially generate sparks – for example sensors, electronic ballast and transmitters.

- Benefit: Cost-effective method for small-scale equipment.

Type of protection (Ex n)

- Principles: Equipment is designed so that it does not create any sources of ignition in normal operating conditions. The design protects against sparking and overheating.

- Use: For all electrical equipment in Zone 2.

- Benefits: Less complex design and more cost-effective.

Optical radiation (Ex op)

- Principle: Various measures prevent ignition of an explosive atmosphere by optical radiation. There are three different methods:

- Ex op is: Inherently safe optical radiation.

- Ex op pr: Protected optical radiation.

- Ex op sh: Optical radiation with interlock.

- Use: Optical communication systems or sensors in hazardous areas.

- Benefit: Special solution for systems with optical technology.

In order to choose the right type of protection, the specific conditions and requirements of the area of application must be taken into consideration. Factors like the actual equipment (function), the type of explosive atmosphere (gas or dust), the temperature class and the mechanical load play a role. A detailed risk assessment is essential in order to work out the ideal type of protection.

These articles might also interest you

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-startseite-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-ueber-den-blog-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-autoren-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-newsletter-expert-mail-279x205.jpg)

Write new comment