Digital Twins in the Process Industry: Practical Benefits Through Asset Administration Shells and Digital Nameplates

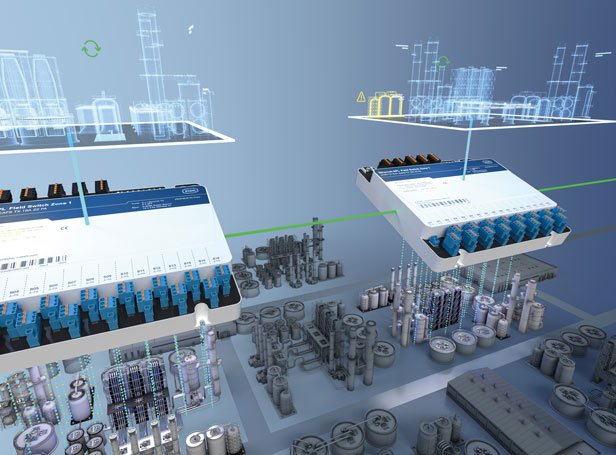

In industrial practice, access to up-to-date, reliable device data is critical – whether for maintenance, planning, or component replacement. In the process industry in particular, the absence of such information can lead to delays and costly downtime. One technological development is increasingly coming into focus: the digital twin – especially when combined with standardized Asset Administration Shells and digital nameplates.

Digital nameplate: enhancing traditional product labeling

Digital nameplates represent an evolution of conventional product labeling. Through QR codes or RFID tags in accordance with IEC 61406, users gain access to structured product information – such as specifications, safety data, or maintenance instructions. This data is centrally stored and accessible at any time via mobile devices or browsers.

For technical operations, this means a significant simplification in handling devices: time-consuming searches are eliminated, and inquiries to the manufacturer are less frequently required.

Asset administration shells as the framework for digital twins

The technical foundation of this development is the Asset Administration Shell (AAS) according to IEC 63278-1. It serves as the digital representation of a physical product and aggregates all relevant information in standardized submodels. This enables not only structured data management but also promotes interoperability between different systems – such as engineering tools, maintenance systems, and ERP solutions.

Such standards are an important step toward avoiding isolated solutions and making digital twins economically viable – not only for large-scale plants but also for small and medium-sized enterprises.

Application scenarios: from maintenance to traceability

- The use cases for digital twins based on Asset Administration Shells are wide-ranging:

- Maintenance: Access to operating and maintenance manuals via the nameplate, even without a PC.

- Product updates: Information on firmware versions and successor products.

- Returns: Automated creation of return forms based on digital device data.

- Documentation: Consistent data availability across the entire product lifecycle.

Asset Administration Shells can also be used in early stages of plant design to consistently integrate product data into CAD, PLM, or automation environments.

Relevance in light of future regulations

Another key aspect is the growing importance of digital product information in regulatory contexts. As part of the upcoming EU Ecodesign for Sustainable Products Regulation (ESPR), from 2026 many industrial products will be required to include digital information on origin, composition, and recyclability.

The Asset Administration Shell provides a suitable structure to meet these requirements – not as an additional burden, but as an integral part of digital product models.

Conclusion

Digital nameplates combined with Asset Administration Shells offer a practical entry point into the concept of digital twins. They enable structured, automated access to device data – delivering concrete benefits for maintenance, planning, documentation, and sustainability.

For companies in the process industry, this creates the opportunity to establish digitalization not as an extra task, but as a systemic part of plant management – without relying on proprietary one-off solutions, but based on open standards.

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-startseite-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-ueber-den-blog-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-autoren-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-newsletter-expert-mail-279x205.jpg)

Write new comment