Before liquefied natural gas (LNG) can be used in process plants or power plants, or fed into the gas pipeline, it must "return to its original form". When it warms up, it reverts to a gaseous state. However, allowing it to do so on its own is not advisable. There are some process and safety aspects that must be taken into account.

What happens at the LNG terminal where the liquefied natural gas arrives after its journey by LNG tanker? Or at the LNG cryotank, which is provided for the power supply of an industrial plant? It makes sense that before the liquefied, cryogenic natural gas (LNG) can be used – in fuel cells or combustion machines, for example – or before it can be fed into the natural gas grid, it must first be turned back into gaseous natural gas. In the simplest case, an ambient air vaporiser is used to do so, through which the liquefied natural gas is fed at -162 °C. Regasification is equivalent to vaporisation. Significantly less energy is required here than for liquefaction of the natural gas. Many preparation processes necessary to extract natural gas have already been completed before liquefaction. Therefore, the freshly vaporised natural gas from LNG is particularly pure, i.e. it comprises around 98% methane.

Don't you simply have to switch off the cooling required to keep LNG at -162 °C (and therefore liquid) and open a valve to the gas pipeline? It's not quite that easy, since humid air would freeze too quickly and conduits would become blocked. Particular procedures described below provide corrective action. The gas produced must also be fed into pipes or plants at a defined pressure.

Safety – always the top priority

Most importantly, however, some elements from a process perspective must be taken into account because natural gas carries the risk of accidents due to its explosive nature. This is why strict safety standards exist. Safety measures must be taken at every stage of LNG regasification and compression of gaseous methane in order to prevent gas explosions, since both natural gas and LNG are highly flammable. Like pure methane, they are classified as explosion group IIA (measure for flammability) and temperature class 1 according to ATEX and IECEx. The ignition temperature of 575 to 670 °C is relatively high. A explosive mixture of air and natural gas is present at a methane content of 4.4 to 16.5 volume per cent. Appropriate explosion protection measures must therefore not only be taken directly at the regasification plant, but also throughout the whole area of the LNG terminal or tank. You can find examples of such measures below.

The process of regasification

Turning LNG back into gaseous natural gas requires it to be vaporised. This occurs through the technical process of regasification in flow vaporisation plants. The heat required for vaporisation is fed into the LNG via a heat exchanger. As the boiling point of LNG is very low, high temperatures are not needed. Generally, the temperature of the surrounding environment is sufficient. This means that regasification can already function with ambient air vaporisers using the temperature in the surrounding environment. The LNG is heated to temperatures of around 20 °C below the ambient temperature. Since the tubes of the vaporisation plant ice over, redundant systems are generally used: While one vaporiser is working, the surface of another vaporiser not currently being used can thaw again. The performance of these simple vaporisers is dependent on weather conditions.

Regasification in the LNG terminal: Seawater can also be used as a heat exchanger in LNG terminals. The gas is then compressed using a compressor before being fed into the gas transmission grid.

Regasification on LNG FSRUs: Seawater is also generally used for regasification on floating LNG storage and regasification units (FSRUs). The vaporised gas is pumped to the port via a short connecting line and fed into the gas grid. FSRUs that are permanently anchored close to the coast are more cost-effective than LNG terminals on land (onshore terminals), and generally are quicker to plan. An additional benefit is that they can be moved to a different location when needed.

Sometimes, submerged combustion vaporisers (SCVs) are also used on terminals and FSRUs. They prevent ice build-up in the heat exchanger tubes. Water from a water bath is also used here as the heat exchanger medium, which comes into contact with the LNG tubes. It is heated using a burner by feeding the combustion gases from the burner into the water bath. The heat exchanger's tube bundles, through which the LNG flows, are located in this water bath. Foam is created, which circulates around the tube bundles, meaning the LNG vaporises inside the tube bundles. The service temperature of the water bath is between 13 °C and 18 °C. An SCV typically consumes 1.3 per cent of the energy of the natural gas it vaporises.

Small-scale LNG plants: Smaller storage tanks or single tanks with LNG can be made available for supplying industrial plants in a decentralised manner, for backup power supply or for decentralised combustion plants, such as combined heat and power stations. Since industrial plants and combined heat and power stations require natural gas, LNG is heated in an ambient air vaporiser before being fed in. The plant technology for these "satellite stations" has been proven successful for years. The heat for vaporisation is taken from the environment. It is possible to transfer the cold from regasification to a brine circuit and to use the cold for air conditioning in residential buildings or cooling in industrial facilities, for example.

LNG as fuel for ships and heavy goods traffic: Regasification is not required here. At "small-scale terminals", LNG is instead used directly to fuel ships or transported in liquid form by tank truck to filling stations. At filling stations, the LNG is pumped into vehicles via a dispenser (filling pump) at a filling pressure of 5 to 8 bar.

In parallel, a second line can be used to fuel CNG (compressed natural gas) vehicles. A pump increases the pressure to between 250 and 300 bar to do so, conveying the LNG to a high-pressure vaporiser in which regasification takes place. The natural gas is fed into the vehicle's tank via a CNG filling pump.

Vaporisation and compression require just one to two per cent of the energy content of LNG that is re-vaporised. Vaporisation is particularly efficient if the cold for the cooling processes can be used for large storage halls in the port, for example.

Transferring the gas to the gas grid and consumer

After regasification of LNG, the natural gas produced is either transported on or provided to a consumer, e.g. a gas-fired power station. Send-out compressors are used for compression in a gas transmission grid, which work in a pressure range of 40 to 100 bar. If, on the other hand, gas is to be fed into a more interconnected distribution grid in which there are lower flow rates, send-out compressors with an end pressure of 20 to 50 bar are used.

Regasification at gas-fired power stations: Gas-fired power stations are often located in the vicinity of LNG terminals or FSRUs. Heat exchangers for regasification and a send-out compressor are also required for their supply. As they can only tolerate low fluctuations in gas pressure so that their gas turbines can reach the maximum possible efficiency, combustion gas booster compressors are often used too, which stabilise the feed pressure for the gas turbine to approximately 50 bar.

Explosion protection ensured at all points

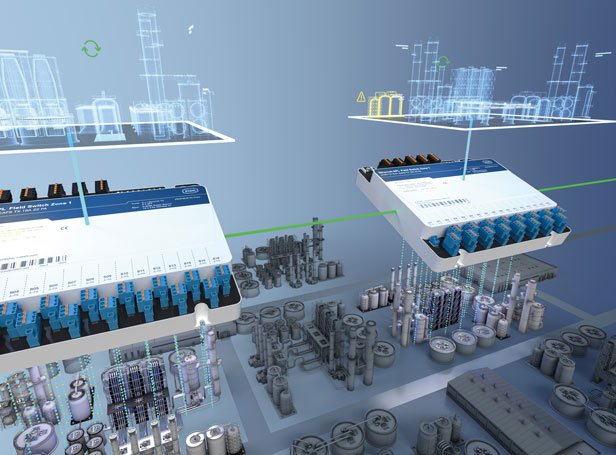

In an LNG terminal, on board an FSRU or at a satellite LNG station, the hazardous zones cover large areas of the plant; as a result, explosion protection solutions from R. STAHL are not only in use during the actual processing stage, but throughout the entire infrastructure. The ignition hazards during regasification and supply to the natural gas grid can be mitigated with construction and electrical explosion protection. Firstly, this means an explosive mixture of natural gas and air should ideally never occur. And if it does, it must not be ignited either by sparks or hot surfaces. This is the job of suitable explosion protection solutions, using devices, protective systems and components that are certified for use with gases in explosion group IIA and temperature class 1. Depending on the application range, they must be classified for Zone 0, Zone 1 or Zone 2 and appropriately certified. To control pumps and compressors, for instance, Remote I/O stations are used, which transmit the signals to a control system in an intrinsically safe manner. Explosion-protected versions of isolators, plugs, sockets, and also luminaires, alarms and camera systems must be used. R. STAHL equips pump units, which convey the seawater to the heat exchanger, with alarm signal emitters, terminal boxes, safety switches and load disconnect switches with AC3 switching capacity. The safety switches safely disconnect the electrical energy supply from machines and system parts for cleaning and repairs.

Explosion protection measures must also be put in place for compressor systems which compress the re-vaporised natural gas before feeding into the gas grid. For example, suitable motor actuators and power distribution boards, which are required for control of compressors, can be made significantly lighter and more compact than conventional Ex d enclosures using R. STAHL's patented EXpressure enclosure technology.

In addition to explosion protection, it is important to select suitable materials and design. The use of seawater-resistant enclosure materials, high-quality sealing materials, a vibration-resistant design, and resistance to electromagnetic influences make a contribution here.

Further Reading:

These articles might also interest you

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-startseite-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-ueber-den-blog-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-autoren-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-newsletter-expert-mail-279x205.jpg)

Write new comment