Digitalisation doesn't stop at Zone 1. Comprehensive networking in the sense of Industry 4.0 can offer the process industry significant advantages when it comes to efficiency, specifically with regards to integral data processing, system monitoring and remote monitoring, predictive maintenance and intelligent diagnostics. Even more important are communications technology solutions that make process data securely available anywhere from the field to the control centre, can be scaled to meet customer requirements and are easy to seamlessly integrate into existing networks. Jürgen Wenzel, Business Development Manager, and André Fritsch, Remote I/O Product Manager, provide a glimpse into technological development.

Mr Fritsch, Mr Wenzel, why does R. STAHL stand out as a system solutions provider for process automation in hazardous areas?

Jürgen Wenzel: First and foremost, we have over 90 years' experience in explosion protection – everything from the relevant preconditions to development, implementation and specific industry requirements. Many system suppliers underestimate the work that goes into development, engineering and ongoing product maintenance in demanding hazardous areas. Our expert sales and applications engineers support our customers from consultation to developing their ideal solution and, finally, to commissioning. But we don't stop there – even after this stage, our customer service team is always available to advise our users. We see ourselves as a partner whose strengths lie in explosion protection; we work hand-in-hand with engineering firms and planning companies who process entire projects.

André Fritsch: Users want to be able to install and use explosion-protected systems without having to spend too much time and effort. This is why we aim to design solutions that are not significantly more complex than comparable systems for non-Ex areas in terms of their function, mounting, handling and maintenance. By and large, we achieve this using three methods: Ex protected enclosure and connection technology, Ex protected product ranges such as our Remote I/O for Zones 1 and 2, and energy-limited signals and interfaces. Correspondingly, we offer a comprehensive portfolio of globally certified products that ranges from individual components for signal and data transmission to visualisation, operating and camera technology. This enables us to take on complex assignments in process automation and to offer tailor-made solutions that allow our customers to transmit their process data for plant control systems from hazardous areas to control systems that control and visualise processes via HMIs in the field and can perform camera monitoring.

What does this mean for technology and product development?

Jürgen Wenzel: During product development and system construction, we take an entirely modular approach. This allows us to combine our components in the manner that best corresponds to the customer's specific intended purpose. Explosion protection should restrict functionality as little as possible. This requires us to have comprehensively mastered all types of protection. We cannot restrict ourselves or our customers to just one or two specific types of protection in the construction design process – we construct systems with the degree of protection most suited to their application. Our wide range of innovative products has made us a technology leader. The most recent example is our patented EXpressure technology, with which we have introduced the entirely new ignition protection concept of pressure relief. As a sole provider, we are in a position to produce Ex d certified enclosures in regular control cabinet sizes – this enables switching system layouts to be transferred from safe areas to hazardous areas without any additional engineering work.

What do users expect from R. STAHL as a system provider?

Jürgen Wenzel: Generally, users don't immediately think in Ex protection categories – they're focussed on their core business. Explosion protection is a complex, safety-critical speciality that requires well-founded specialist knowledge and experience. Staying up-to-date with the latest technology in this sector requires significant effort. Our customers cannot be experts in every standard- and technology-related area. They therefore expect us to provide them with a solution that meets their specifications, is certified according to applicable standards and has been tailor-made to suit the specific conditions of use on-site.

André Fritsch: As a certified manufacturer, we are authorised to construct Ex systems designed to customers' specifications and to certify systems without external test bodies. This saves our customers lots of time and money. This also includes solutions for hazardous areas that are classified as Zone 2 by system operators. In this sector, we have always held ourselves to a high standard. Nowadays, we offer tested, certified device specifications for almost all product ranges that completely fulfil all safety criteria. Beyond Ex protection, we support users in the process of obtaining further certifications such as SIL classification, FDA and GAMP validation or granting ship approvals. Since Ex technology is often outsourced to specialised manufacturers, comprehensive support with parameterisation, installation and commissioning is in high demand. This is why we design our systems uniformly so that they are easy and safe to install and maintain.

So how different are the challenges that you face?

Jürgen Wenzel: Our system solutions are used in every corner of the globe. The challenges we face are just as varied as the locations where our system solutions are used. We have a global network of automation experts with in-depth knowledge of regional requirements. This doesn't just refer to standards, but also specific safety and environmental stipulations, as well as the environmental conditions at the operating location. Take, for instance, the oil and gas industry – oil production platforms and refineries are found in all climate zones, from deserts to polar regions. Switching, control and communication technology, operating and display units, and lighting systems must be designed to withstand corresponding temperatures. As a result, we offer product ranges for our entire portfolio that are designed for extreme temperature ranges. We also equip our explosion-protected switching and control combinations with additional heating or cooling units as required. Additional challenges arise in the maritime sector due to increased salt content, moisture and increased vibrations. Since installation space on ships is limited and customers aim to save every gram of weight possible, our designs must be particularly compact and lightweight.

Can you give any concrete examples?

André Fritsch: For maritime applications, we develop specific system solutions in a robust, vibration-resistant and corrosion-resistant design. Our Remote I/O IS1+ has already been developed from scratch for these operating conditions and is used for intrinsically safe signal transmission on tankers. This system enables sensor data to be forwarded from gas liquefaction compressors in Zone 1 to the control room via a bus system. Our solution, which has been perfected over time, has been granted twelve different ship approvals, from DNV-GL to ABS and ClassNK, for global use and has since established a foothold as the standard in the LNG sector. In the meantime, around 80% of all liquefied gas tankers use this system on board. Thanks to the 8- or 16-channel Ex i modules, it can be designed in an especially compact and lightweight version, is easy to expand using Plug & Play in continuous operation without any complicated procedures, and fulfils strict maritime requirements for EMC protection, seawater resistance and vibration resistance. Another example can be seen in the chemical industry – in this sector, a plant operator had initially opted for one of our competitors' products, only to find that the design of their systems varied hugely between Zone 1 and Zone 2, and that the permissible temperature ranges were very different. With our Remote I/O, this customer now benefits from a coherent solution with a uniform operating concept, manageable number of components and simple spare parts management.

How are you ensuring that the Remote I/O is future-proof with regards to new trends in process automation?

Jürgen Wenzel: Our Remote I/O systems are extremely long-lasting and reliable. This is demonstrated by the fact that they have been in use in some systems for more than 20 years, only requiring minor modifications in this time. If modernisation is then due, operators often choose to convert their system to IS1+. This system offers the ideal solution for bringing an existing installation into the digital Ethernet age without the need for major conversion work. With IS1+, we currently offer the latest and most cost-efficient digitalisation platform. Preventative diagnostics, IP communication, redundancy solutions, extended temperature ranges and additional future features have already been installed. And, very importantly for our users, it is completely backward-compatible with the preceding system. This is always a high priority for us when developing new products. Our Remote I/O with Ethernet connection is also popular among our customers because it is able to plan the migration path and adjust the required communication protocol itself. This means that users never need to change everything over from one day to the next – they can continue to work with existing solutions until the new network connection is available.

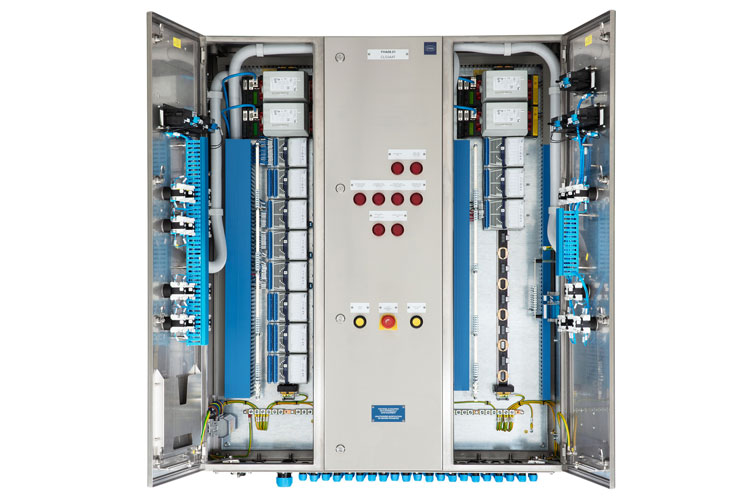

The intrinsically safe and non-intrinsically safe sensor/actuator signals integrated via the explosion-protected IS1+ remote I/O system for zones 1, 2 and Class I Div. 1, 2 can be communicated to the process control system via PROFIBUS DP, Modbus, Ethernet Modbus TCP, EtherNet/IP or PROFINET. Thanks to the eight- or 16-channel I/O modules, which are suitable for a wide range of signal types, the stations can be set up very compactly and, compared to conventional solutions, extremely space- and weight-saving. The remote I/O system also offers a significant advantage due to the possibility of expanding the installation at any time according to the plug-and-play principle: All modules can be added or changed on site during operation in Zone 1 or Class I Div. 1, if required. The intrinsically safe process bus can be operated with either copper or fibre-optic cables and, if required, can be designed redundantly or as a ring. In the IS1+ remote I/O system, eight-channel analogue input/output modules with HART, 16-channel digital input/output modules, four- and eight-channel digital output modules and eight-channel temperature modules for resistance thermometers and thermocouples are available. The signals can be parameterised individually for each channel. Mixing modules enable effective solutions for rather low signal volumes and reduce spare parts inventory by 50 percent. Thanks to low-power technology specially developed for the IS1+ I/O level, the modules are suitable for an extended temperature range of -40 to +75 °C and achieve a long service life of typically 15 years. Extended diagnostic options offer users practical advantages; all Zone 1 modules have one or two LED indicators per channel. In the case of analogue modules, line faults are signalled via a red LED; in the case of digital modules, the switching status is additionally indicated via a yellow LED. All modules are equipped with additional self-diagnosis functions in accordance with NAMUR NE 107, so that the warning message "maintenance required" is sent twelve months before the end of the expected service life. In addition, the need for maintenance is clearly signalled by a blue LED on the module. Another new feature is the status bit for process signals, which displays values as qualitatively "good" or "bad", similar to field buses.

Fully redundant: IS1+ station for refinery outdoor use in zone 2.

With the advance of digitalisation, more and more IP-based transmission paths are being used instead of fieldbus systems. What effect does this have on process automation in hazardous areas?

André Fritsch: For Ex protected data transfer, we offer everything from fieldbus connections to fibre optics and from Ethernet to Wi-Fi communication – always guaranteeing that the solution we provide is optimally suited for the user's application in terms of its function and cost. Just recently, we constructed a wireless system on an oil production platform which is so flexible that the customer can choose which wireless technology they want to use before they even start up the system. Nowadays, digital bus solutions such as PROFIBUS DP or Foundation Fieldbus H1 are installed in the majority of systems. Industrial Ethernet technology is now taking things to the next level. It differs from conventional Ethernet technology primarily in its installation technology – all of its components, including cables, plug connectors, switches and media converters, need to be made significantly more robust. In order to provide our customers in the oil, gas, chemical and pharmaceutical sectors with Ethernet solutions for hazardous areas, we have developed a wide portfolio based on different types of protection. This includes Ex e protected connection terminals for copper cabling, as well as isolators and splice boxes in Ex op versions for inherently safe fibre optics; the range also features intrinsically safe signal and data transmission with Ex i protection type, which we also use to control antennas for Wi-Fi communication. R. STAHL is involved with a number of organisations, with the aim of helping to shape the future and drive digitalisation in hazardous areas at the forefront of technology. As well as our work with European and international standardisation bodies, we are actively working on future technology-related matters such as Ethernet Advanced Physical Layer (Ethernet-APL), NAMUR Open Architecture (NOA) and the Open Process Automation Forum (OPAF).

Further Reading:

These articles might also interest you

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-startseite-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-ueber-den-blog-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-autoren-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-newsletter-expert-mail-279x205.jpg)

Write new comment