Incorrect storage of hazardous chemical substances and inadequate surveillance of storage areas all too often result in catastrophic industrial accidents. In June 2020, a container with toxic chemicals exploded in a chemical factory in India, resulting in a catastrophe that claimed the lives of eight workers, with a further 74 sustaining injuries, some of them life-changing. It took fire fighters five hours to get the fire under control. Only two months later, this terrible accident was overshadowed by events in Beirut. An explosion of ammonium nitrate containers devastated large areas of the Lebanese capital. At least 190 people died, and over 6,000 were injured.

Spotting dangers

Since the uncontrolled interaction of hazardous substances, oxygen, heat or sparks poses an extremely high risk for life and systems, the storage and monitoring of dangerous substances in hazardous areas is one of the most important tasks of plant operators. Particular caution is required if hazardous substances are stored in containers. Container fires are notoriously difficult to fight, because there are usually large amounts stored and access is difficult. What is more, in many cases there is an increased risk of subsequent fires or multiple explosions. For such incidents, fire brigades not only have to work at full capacity, employing large numbers of staff on the callout, but they also need specific expertise in fighting chemical fires. Consequently, fire brigades across the world are highly sensitised to callouts to chemical environments.

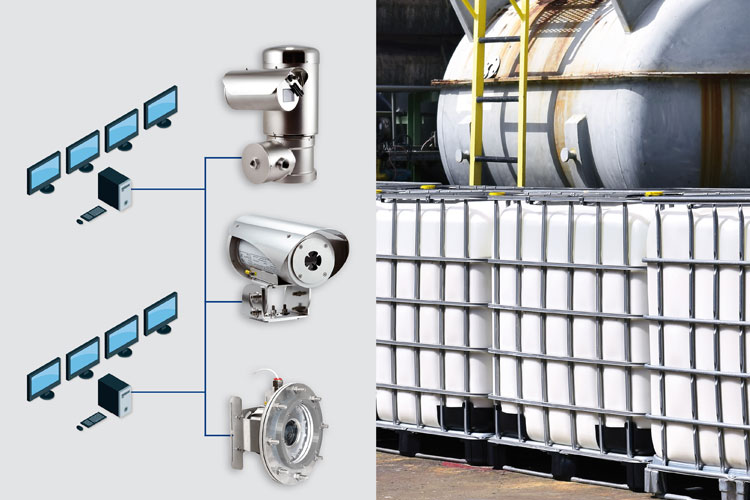

For the surveillance of containers, tanks, piping and other potential sources of fire, we recommend customised CCTV systems that can be flexibly adapted to suit different parameters and local conditions.

Detailed analysis of hazard

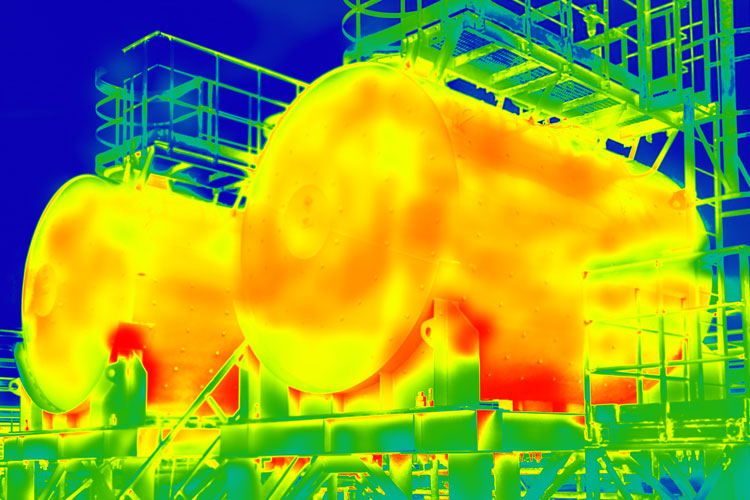

To ensure a reliable detection of a hazard source when monitoring containers in hazardous areas and simultaneously prevent costly false alarms, our explosion-protected IP thermal imaging cameras now also feature separate detection of flame movement and temperature. This function means that the intelligent cameras can clearly distinguish whether there is "only" a flame-like movement or whether the temperature has also risen above the pre-defined limit. A measuring module distinguishes temperatures in the video recording pixel by pixel. Only once the pre-defined temperature levels are exceeded will the programmed alarm procedure be triggered. These reliable fire and warning alarms increase surveillance security in hazardous areas, whilst greatly reducing false alarms and their associated cost. Furthermore, CCTV systems with thermal imaging cameras can monitor large areas with corresponding thermal images: depending on the type of thermal imaging camera, areas of a size of up to 650 m² can be monitored in great detail.

An integrated concept is the key

Even the latest thermal imaging cameras cannot ensure sufficient fire protection if used by themselves. Only the combination of explosion-protected cameras, industrial cameras where needed and associated software can ensure a sufficient level of protection. In chemical and pharmaceutical companies, for example, piping, transport routes and loading/unloading stations are monitored with fast-panning PTZ cameras (pan/tilt/zoom). These types of camera cover all surveillance points programmed in a virtual guard tour, and they can precisely zoom in on selected spots within 0.2 seconds. If the virtual guard tours also cover areas that should remain hidden, these can be blacked out with the "Dynamic Masking" function. Because this blacking out is dynamic, the specified areas will remain blacked out regardless of the panning and zooming motions of the camera. Because of their large range of functions, including precise 360° panning, fast and precise focussing and the high-quality images with electronic image stabilisation, PTZ cameras are today used in many different applications.

Looking into every nook and cranny

Chemical or pharmaceutical plants have many secluded areas that are difficult to view from afar. For such cases, AFZ (autofocus/zoom) cameras are particularly suitable for indoor monitoring. To cover the entire premises including zones blocked from direct view, we recommend positioning several cameras so that they provide seamless coverage, with each camera taking on part of the view and the combination of all cameras providing a complete overall view of the locality. Our AFZ models have been designed for temperatures ranging from -55 °C to +65 °C for continuous, 24/7 surveillance even under extreme conditions. The devices, certified for operation almost everywhere across the world, not only can resist considerable temperature fluctuations, but also salt spray and vibrations.

An inside view

For monitoring tanks and reactors through sight glasses, sight-glass cameras can be exactly positioned on top of the sight glass and provide clear, bright images of all processes inside due to their high degree of light sensitivity. If a process suddenly generates foam, the direct image transfer to the control room allows for a much faster intervention by staff than would be the case with guard tours.

All-seeing eye for outdoor areas

Dome cameras are available for wide-reaching, 360° monitoring of hazardous outdoor areas and complete plant sections. Located under a transparent dome, the pan and tilt camera with 18x or 40x optical zoom can also provide close-ups and enlargements of conspicuous or dangerous locations. Also, unauthorised personnel or wrongly placed goods can immediately be spotted for prompt intervention.

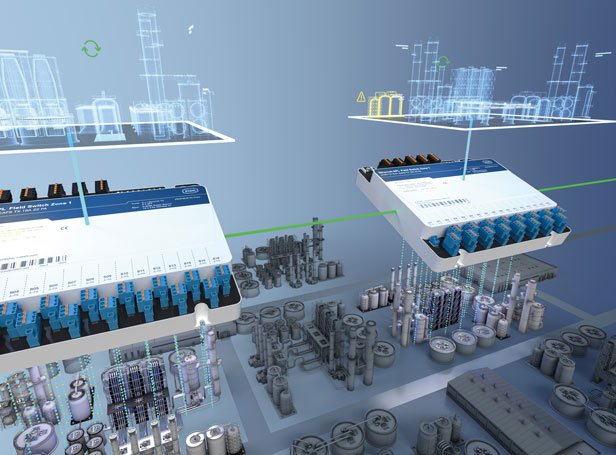

All information is pooled by a video management software, which, depending on its range of functions, becomes a key part of any highly professional surveillance solution. Ideally, this would be a modular, upgradeable software solution to map all industry-specific complexities. Powerful alarm management concepts should be standard, as well as easy-to-use video players, configuration assistants and an analytics interface for integrating other analysis software. In addition, there should also be the option of integrating third-party systems for physical security information management, access control as well as break-in and fire alarms.

R. STAHL specialises in project engineering, equipment and implementation of customised video surveillance solutions for hazardous and industrial areas. The company is one-stop-shop offering the entire range of services from CCTV planning, project management, FAT and SAT acceptance, commissioning, engineering and full product training. If required, project managers will carry out site inspections for a customised CCTV system, supporting users as the central contact person for the implementation of individual surveillance solutions.

In addition to developing new systems from scratch, R. STAHL will also integrate camera systems into existing CCTV systems. Expert staff will analyse the existing system, and on this basis develop further configuration levels and upgrades. The customers profit from a reliable planning basis, smooth production and delivery processes and the professional realisation of all requirements.

R. STAHL's camera portfolio comprises a wide and varied selection: all-rounder cameras, dome cameras, compact cameras and zoom cameras with suitable video management software.

Further Reading:

These articles might also interest you

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-startseite-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-ueber-den-blog-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-autoren-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-newsletter-expert-mail-279x205.jpg)

Write new comment reply