The pharmaceutical, food and cosmetics industries are governed by strict regulations. Products have to be produced, controlled and documented according to the rules of Good Manufacturing Practice (GMP). At the same time, many systems require explosion protection (Ex area) Technical equipment such as operator stations consequently needs to be equally hygienic, safe and reliable.

Typically, operator stations consist of:

- Display unit: one or several screens to display information such as process data, status reports or alarms.

- Operating elements: keys, touchscreen, trackball or other input devices to control functions.

- Interfaces: connection to control systems (such as PLC, DCS), networks or other devices.

- Integrated inside an enclosure for installation in cleanrooms or hazardous areas.

Hygiene requirements for HMIs

International standards and directives specify clear requirements to prevent contamination. Some of these are:

- EU-GMP Annex 1 (sterile production)

- EHEDG (hygiene-compliant machine design)

- ISO 14159 (hygiene requirements for machine design)

- DIN EN 1672-2 (food production machinery –- hygiene)

- ISO 14644-4 (Clean room technology – surfaces)

- VDI 2083 (Clean room technology)

A striking detail: the standards do not directly define the design of an operator station. Instead, they specify the clean room requirements and deduce from this suitable materials and designs.

Important aspects of HMIs in hygienic environments are:

- smooth, non-porous surfaces,

- easy to clean,

- rounded edges,

- resistance to cleaning agents and disinfectants,

- no deposit of particles due to static charge

Clean rooms and qualification

A frequent misunderstanding: equipment cannot be "certified for clean rooms". Instead, operators have to check and document suitability according to the directives. Operator stations are suitable for clean rooms class D and C. For the two highest classes A and B we usually recommend the integration of the HMI inside a wall so as not to obstruct airflow.

Regulations concerning automation systems

In addition to hygienic design, the validation of automation systems also plays a major role.

- GAMP (Good Automated Manufacturing Practice) specifies guidelines for development and operation.

- FDA 21 CFR Part 11 describes the requirements for electronic recordings and signatures.

According to these, HMIs have to be able to support secure user registration, access control and electronic signatures, for example via RFID solutions.

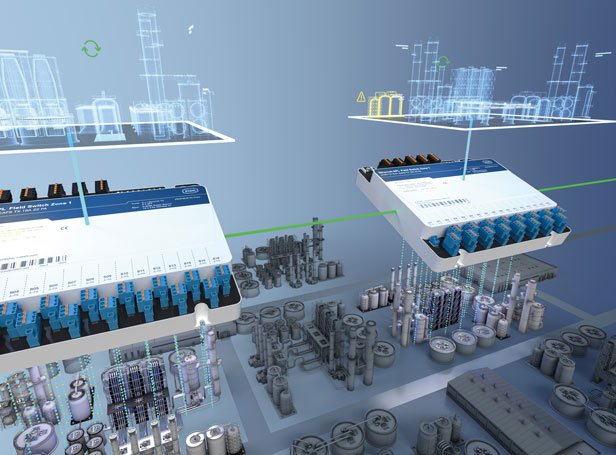

Explosion protection in regulated environments

In addition to GMP-compliant design, many production facilities are also subject to explosion protection considerations. Operating stations for hazardous areas are subject to different regulations worldwide, but these are based on standards such as ATEX and IECEx.

Typical areas of application are:

- Zone 1 / 21 (Ex atmosphere likely),

- Zone 2 / 22 (occasional Ex atmosphere),

- safe areas.

Certifications have to be checked at regular intervals - the relevant valid certificates are included in the operating instructions.

Conclusion

Operator stations in the GMP-regulated industry must fulfil a complex requirement profile: hygienic design, easy to clean, support of validation directives and – depending on the location – explosion protection. Instead of looking for a blanket "clean room certification", operators should familiarise themselves with the underlying standards and the qualification of the devices in their own environment.

These articles might also interest you

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-startseite-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-ueber-den-blog-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-autoren-279x205.jpg)

![[Translate to Englisch:] [Translate to Englisch:]](/fileadmin/user_upload/mitarbeiter/01_DE/07_Blog/00_Allgemein/blog-explosionsschutz-rstahl-newsletter-expert-mail-279x205.jpg)

Write new comment